Theran storage area - part 1.

In the summer of 2006, I traveled by KLM Royal Dutch Airlines Boeing 767-200, from Amsterdam to Tehran, to attend the first Air Events aviation tour to Iran. During my stay in Tehran, I took the opportunity to spend some time at Tehran's Aviation & Space Exhibition Center and the adjacent aircraft storage area.

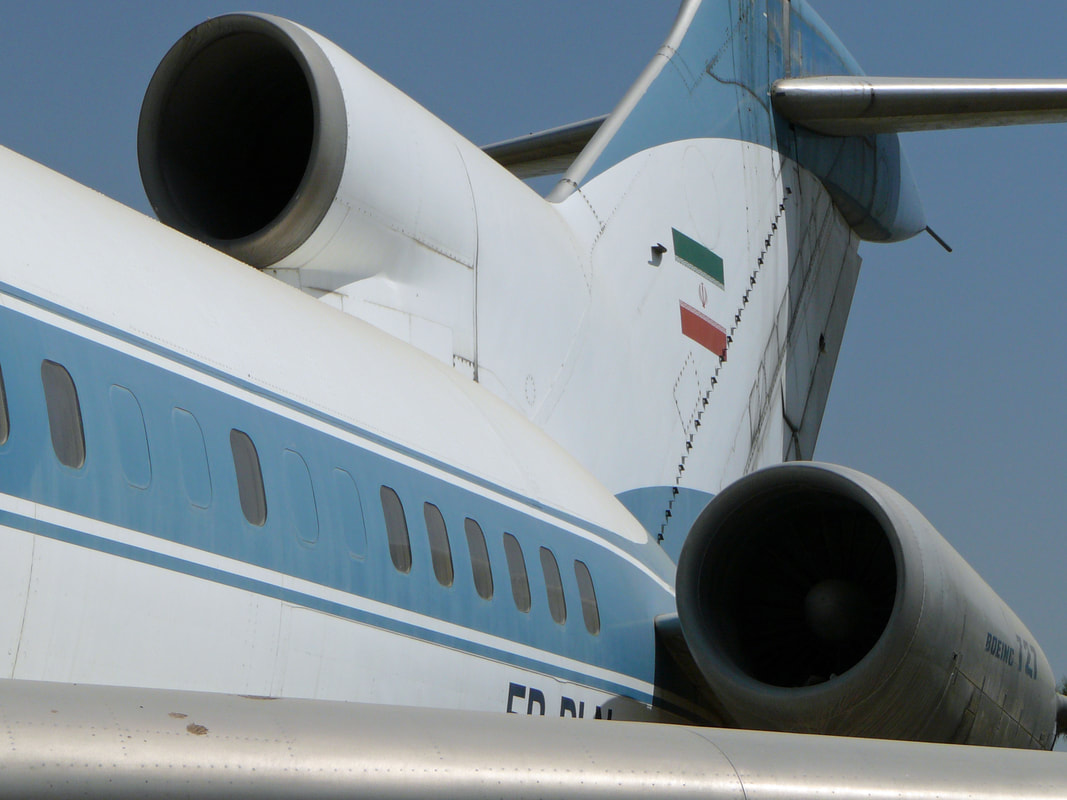

This vintage Boeing transport forms a fitting frame for some classic jets lined up at Theran - Merabad in 2006.

Neat pic. I flew the 727-100 and 737-200 both great birds.

Once a common sight around European airports. Delivered in 1964 to Lufthansa, this aircraft, christened ‘Mannheim”, has since been sold by the German carrier and was already in March 1976 exported to Iran.

|

The 727 proved to be such a reliable and versatile airliner that it came to form the core of many startup airlines‘ fleets. The 727 was successful with airlines worldwide partly because it could use smaller runways while still flying medium—range routes. This allowed airlines to carry passengers from cities with large populations but smaller airports to worldwide tourist destinations. One of the features that gave the 727 its ability to land on shorter runways was its clean wing design. With no wing—mounted engines, leading—edge devices and trailing—edge lift enhancement could be used on the entire wing.

|

Boeing initially forecast sales of around 300 727s, but they ended up building no less than 1831.

Billboard titles.

The earlier short-fuselage version has not retained the high second-hand values associated with stretched late-build 727-200 and -200 Advanced airframes built towards the end of the production line in 1984.

Below the pilot's windows, gray water streaks flowed towards the belly.

The eyebrow windows were originally used in tight turns to help the pilots align with the runway. However, nowadays, it doesn't really add that much visibility. All it really does is just have the sun shine into the pilots' eyes. Pilots usually cover them up with IFR charts, or checklists. They look cool on the outside. But they're not great on the inside. In addition, the more windows you have on an aircraft, the more time you spend cleaning, checking them, etc. So, by removing the eyebrow windows, some maintenance time was saved.

The 727 was significant to the development of today's air transportation system. The earliest model 727s entered service in 1964, helping bring the first pure jet service to many smaller communities. A unique high—lift wing design, its rakish "T—Tail," and three powerful aft-mounted turbofan engines allowed the 727 to economically serve airports too small for the larger first-generation jetliners, like the four—engine Boeing 707 and Douglas DC-8. There were 1,832 Boeing 727s produced - a production run surpassed only by the 2,800 Boeing 737s built thus far.

Below the pilot's windows, gray water streaks flowed towards the belly.

The result was a graceful design with a high cantilever T-tail and a large swept wing.

When prototype 727 -E-1 made its maiden flight on February 09, 1963, one of the more unexpected phenomena experienced was a series of compressor stalls in the center engine. The problem was traced to turbulent airflow caused by the oval shape of the intake in the tail-mounted number two engine. As can be seen from this photograph of an Evergreen International airlines Boeing 727-30C, the company decided to stick with the original external design which remains a distinctive feature of the shorter-100 series. The turbulent flow characteristics and the engine surges, were cured by lining the inside of the large snake-like ‘S-duct’ which feeds air to the engine, with vortex generators (VGs). These are tiny projections more frequently seen on the upper surfaces of wings and in this case, the skin of the vertical tail. Each projection juts out through the slower moving air just above it. The VG causes the faster airstream to swirl into the slower one, so re-energizing the flow and helping it to sick more smoothly to the surface.

The Pratt & Whitney JT3D engine was the major powerplant for the 707 and helped provide the springboard for P&W to launch the JT8D – the most successful jet engine in history.

Within the fan inlet case of the JT8D, there are anti—icing air bosses and probes to sense the inlet pressure and temperature. Similar units exist throughout the engine to check temperatures and pressures.

The reverse thrust system on the 727 JT8D's uses clamshell—type doors on each engine to deflect exhaust gases in a forward direction. The 727's reverse thrust system is not designed to be used in flight. It can be used to back the aircraft, but great caution should be used at speeds of less than 70 knots because of possible exhaust gas ingestion and engine damage.

Close-up of the vertical stabilizer of the 727. The small vanes are vortex generators, which delay airflow separation and improve the effectiveness of the stabilizer and rudder.

Boeing originally planned to power the 727 with the Rolls-Royce Spey, but was forced to abandon this when Eddie Rickenbacker, president of launch customer Eastern, refused to accept the idea. Boeing then approached Pratt & Whitney, who developed the JT8D from a military engine. The JT8D has since become the bestselling commercial jet engine in history, with more than 14,000 produced.

The 727 was the first commercial airliner to be fitted with triple-slotted trainline edge flaps. These intricately engineered flap system, added to the full-span leading-edge flap, increase wing area by 25 per cent when fully deployed and help dramatically reduce the 727’s take-off and landing distances.

The first of the line, the name “707”, was picked simply because it was catchy. Since then it has been only to build on that base of publicity and continue the naming sequence.

Boeing originally planned to power the 727 with the Rolls-Royce Spey, but was forced to abandon this when Eddie Rickenbacker, president of launch customer Eastern, refused to accept the idea. Boeing then approached Pratt & Whitney, who developed the JT8D from a military engine. The JT8D has since become the bestselling commercial jet engine in history, with more than 14,000 produced.

The 727 was designed for smaller airports, so independence from ground facilities was an important requirement. This led to one of the 727's most distinctive features: the built—in air stair that opens from the rear underbelly of the fuselage, which initially could be opened in flight. Hijacker D. B. Cooper parachuted from the back of a 727 as it was flying over the Pacific Northwest. Boeing subsequently modified the design with the Cooper vane so that the air stair could not be lowered in flight.

Islamatic Republic of Iran Airlines used their luxury 727's to tailor to clientele who are used to leading ‘lifestyles of the rich and famous’.

Did Shah Momammad Reza Pahlavi or Ayatollah Khomeini ever used this lav?

This Executive version of Boeing's 727 offered airliner reliability, flexibility and cabin space, with the luxury of a private jet interior.

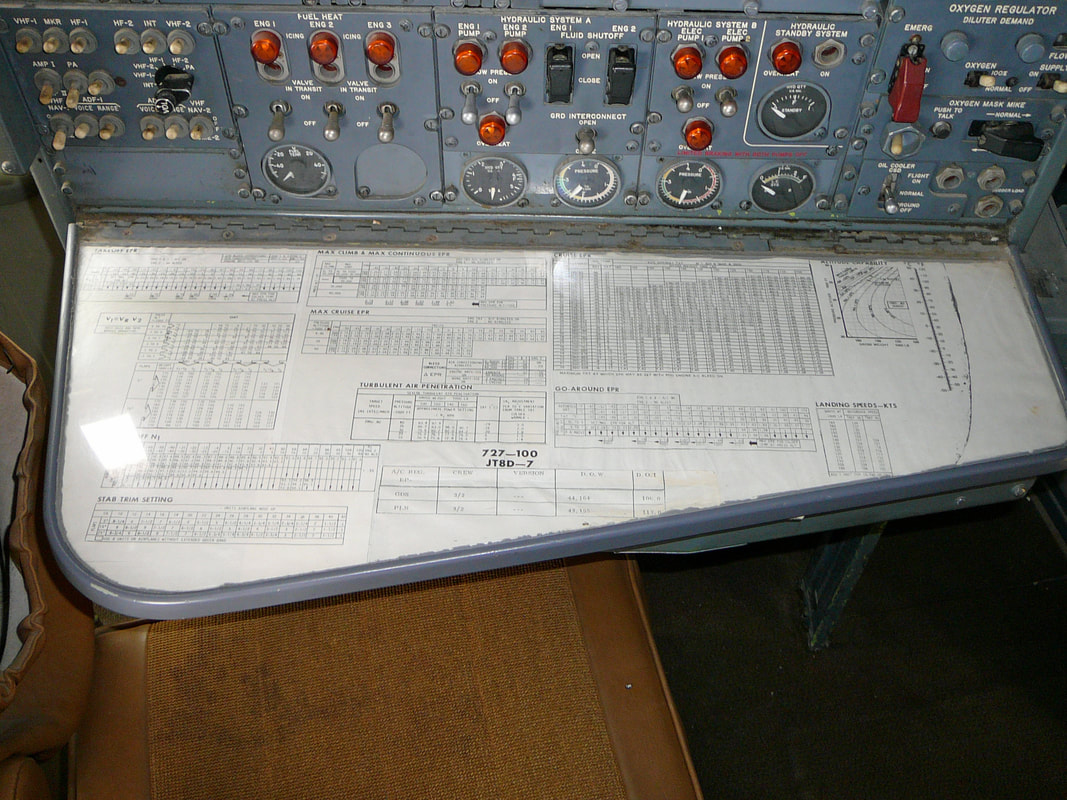

The front office of EP-PLN, but can a photograph communicate the feel of this wonderful machine?

Your author at the helm of EP-PLN in 2006.

The RED handle is the Boeing 727's pneumatic hand brake.

Radio's and thurst control column.

The fact that the 727 needs a flight engineer has been one of the main reasons for its eventual departure from frontline airline service.

One of several reason given by the airlines for retiring its faithful 727 workhorse is the high operating costs of a three-man crew versus the efficiency of a two-man operation.

Boeing 727-86 EP-IRC. With a clipped cockpit her service life seems over.

Fokker F-28-4000 is one of a number operated by Iran Aseman Airlines on the company's network.

IAA stands for Iran Aseman Airlines.

Again, we got rewarded with bright sunshine on this lovely Thursday, August 30, 2006.

EP-ASE resting under a gorgeous sunset in Theran. This 27 year old Fokker F-28-4000 Fellowship had a busy first 15 years of life, criss-crossing the European sky for Air Anglia, Air UK, Air Alsace and Transport Aerien Transregional (TAT).

According to a user from Iran, the name Aseman is of Persian origin and means "Sky".

This stunning photograph help capture the essence of the lost age of the early turbofans and turbojets.

The Fellowship had a retractable tricycle landing gear which used large low pressure tires, enabling the use of unpaved airstrips. The use of anti-skid brakes on the main wheels of the undercarriage also contributed to a shorter landing run.

A sad, Fokker F-28-4000 Fellowship sits in the sunshine at Theran - Merabad airport, awaiting an uncertain future.

F.28 Mk 4000 was approved on 13 December 1976. It was built on the longer Mark 2000, with two overwing exits on both sides, a 60 in (1,500 mm) wing span extension, and capacity for 85 passengers. The first prototype appeared on 20 October 1976 and it began service with Linjeflyg (Sweden) at the end of the year.

The F28 is powered by a pair of Rolls-Royce Spey turbojet engines. While the feature was available at the time, Fokker chose not to equip the engines of early F28s with a water-methanol injection system as they determined that the engines already possessed sufficient performance even when being flown under hot-and-high conditions. The majority of onboard systems are designed with simplicity in terms of operability and serviceability; there was no hydraulic system, actuation of the undercarriage and steering relied on pneumatic pumps instead. However, the F28 was outfitted with comparatively advanced electronics, as Fokker's design team viewed this factor as directly relating to overall competitiveness.

The Fokker F-28 Rolls-Royce Spey engines are fitted with distinctive exhaust tail cone.

Unfortunately, the hallmarks captured so well by the lens, also spelled the doom of these geriatric jets.

One uncommon feature of the F28 was the movable split-sections installed upon the tail cone; these would be hydraulically-opened outwards to act as a variable air brake. A similar approach had also been used on the later-built British Aerospace 146 regional airliner. The design is unique in that it not only slows the aircraft down rapidly, it can aid in rapid descents from economic cruising altitudes and also allowed the engines to be set at higher RPM which helped eliminate 'lag time'. This means the engines respond faster if needed for sudden speed increases or go-arounds on the approach to landing.

Their once bright liveries looking dull in the strong summer sunlight. These Iran Air jets formed a fraction of the vast fleet of ‘Huma birds’.

EP-IGA had faded paint and flat tires during my visit in September 2006.

Almost 32 years old at the time this photograph was taken, EP-IGA had already seen 23 years of service with Iraq Airways as YI-AGH, when the aircraft was confisticated by the Iranian after the first Iraq war.

The original 737-100/200 thrust reversers were pneumatically powered clamshell doors taken straight from the 727. When reverse was selected, 13th stage bleed air was ported to a pneumatic actuator that rotated the deflector doors and clamshell doors into position. Unfortunately they were relatively ineffective and apparently tended to push the aircraft up off the runway when deployed. This reduced the downforce on the main wheels thereby reducing the effectiveness of the wheel brakes. By 1969 these had been changed by Boeing and Rohr to the much more successful hydraulically powered target type thrust reversers. This required a 48 inch extension to the tailpipe to accommodate the two cylindrical deflector doors which were mounted on a four bar linkage system and associated hydraulics. The doors are set 35 degrees away from the vertical to allow the exhaust to be deflected inboard and over the wings and outboard and under the wings. This ensures that exhaust and debris is not blown into the wheel—well, nor is it blown directly downwards which would lift the weight off the wheels or be re-ingested. Fortunately the new longer nacelle improved cruise performance by improving internal airflow within the engine and also reduced cruise drag. These thrust reversers are locked against inadvertent deployment by both deflector door locks and the four bar linkage being over center.

The 'series 200' APU air intake is clearly visible below the Boeing 737 marking.

These little piggies had big tubes under their wings and were relatively smoky!

The airplane's paint has faded extremely due to ultra—violet exposure.

For the Boeing 737-200 aircraft, each Pratt & Whitney JT8D—9A engine is equipped with a clamshell—type (also called bucket—type) thrust reverser. A clamshell—type reverser uses two deflector doors, an upper and a lower door, installed on the aft end of the engine. When forward thrust is selected, those deflector doors are stowed and form the external cowling around the engine exhaust nozzle. When reverse thrust is selected, the deflector doors are moved aft and rotated to the position of about 30 degrees from the vertical in order to block and redirect the turbine exhaust gas flow. Exhaust gases are deflected forward and result in reverse thrust, which is directed rearward, instead of forward.

Resplendent in full Iran Air livery, this derelict Boeing 737-286C can be found on the north-eastern rim of Theran - Merabad Airport.

The pitot tube on the tail is for the elevator feel and centering unit.

EP-IRF; - This scruffy 'Baby-Boeing' has spent its entire life with Iran Air flying passenger's services in the Middle-East.

Most 737 cockpits are equipped with eyebrow windows positioned above the main glareshield. Eyebrow windows were a feature of the original 707 and 727. They allowed for greater visibility in turns, and offered better sky views if navigating by stars. With modern avionics, they became redundant, and many pilots actually placed newspapers or other objects in them to block out sun glare. They were eliminated from the 737 cockpit design in 2004, although they are still installed at customer request. These windows are sometimes removed and plugged, usually during maintenance overhauls, and can be distinguished by the metal plug which differs from the smooth metal in later aircraft that were not originally fitted with the windows.

An airplane stored outside will be subject to streaking down the paintwork from dust and dirt deposits unless washed regularly.

Weathered, but still as good a looker as the day she rolled off the Renton production line.

This Boeing 737-286 was operated by Iran Air as EP-IRH since August 1971.

The JT8D tailpipe was fitted as standard from c/n. 135 onwards because the original thrust reversers were totally redesigned by Boeing and Rohr since the aircraft had inherited the same internal pneumatically powered clamshell thrust reversers as the 727 which were relatively ineffective and apparently tended to lift the aircraft off the runway when deployed! The redesign to external hydraulically powered target reversers cost Boeing $24 million but dramatically improved its short field performance which boosted sales to carriers proposing to use the aircraft as a regional jet from short runways. Also the engine nacelles were extended by 1.14m as a drag reduction measure.

A major point in removing the eyebrow windows on the latest Next Generation 737's is reduced costs on maintenance. Pilots usually blocked them with paper or similar, for most of the flight, if its sunny!

Crying out for cosmetic attention.

Decorative painting are expensive. Cost can run anywhere from $50K to $200K per plane.

Below the wingroot we can find the RAM-air inlet.

Aging aircraft repairs have typically involved upper-skin lap fastener replacement, nonbonded skin panel replacement, skin lap doubler repairs, frame reinforcement, entryway door and scuff-plate doublers, replacement bushings and clevis joints, bulkhead forging replacement, and selected landing gear component replacement.

This Boeing 737-200C stood outside for over a years at Theran Merabad without any maintenance. Dirt has gathered in all the panel lines showing most clearly around the doors and windows.

Looking to transport several employees, a large amount of cargo, or bring an entire team and its heavy equipment to your oil drilling site? - In the 70/80's Iran Air had the solution; - their fleet of Boeing 737-200 Combi aircraft could met every requirement.

Iran Air had Boeing customer code ‘86’ so EP-IRI became a 737-286.

- Model 737-100: initial version (102 passengers) with JT8D-9 engines.

- Model 737-200: first ‘stretched’ version with lengthened fuselage.

- Model 737-200C: convertible passenger/cargo version.

- Model 737-200QC: quick-changed version of 737-200C.

- Advanced 737-200: improved version introduced in 1969: aerodynamic and other refinements, permitting short-field operation.

Unfortunately out of service and resting is Boeing 737-286C EP-IRI. Beside the missing engine the plane still looks good.

Dumped alongside company Boeings in the Aeronautical Compound of Theran - Merabad is this Boeing 737-286C, registration EP-IRI, still wearing faded Iran Air marking.

Iran Air, branded as The Airline of the Islamic Republic of Iran, Boeing 737-286C, with the Huma bird sporting majestically on its ventral fin, seen here in storage at Tehran, Mehrabad airport.

Paint chipping, dents and scratches all happen during maintenance. Panels and cowls are frequently removed resulting in replacement screws and distorted panel edges. The replacement screws are unlikely to be painted. Paint will wear away on areas frequently walked on or held, such as the wing roots and hand holds etc.

Auxiliary inlet doors were fitted to early JT8D’s around the nose cowl. These were spring loaded and opened automatically whenever the pressure differential between inlet and external static pressures was high, i.e. slow speed, high thrust conditions (takeoff) to give additional engine air and closed again as airspeed increased causing inlet static pressure to rise.

Iran Air Boeing 737-286 is heading for no-where under an overcast Septermber sky in 2006.

Aft body vortex generators; - vortex generators became an optional retrofit in November 1968 to reduce “vertical bounce” during cruise flight which was caused by airflow turbulence and separation from the body beneath the horizontal stabilizer. The 1968 modification was to install the three lower aft body vortex generators and another on the underside of the horizontal stabilizer near the body. The stabilizer vortex generator was removed in 1971 due to higher than expected in-flight loads and the four upper aft body vortex generators were added instead. These modifications were all optional because not all aircraft exhibited the vertical bounce. The full set of vortex generators were installed at production from 1971. Classics were initially produced without any aft body vortex generators. However the upper vortex generators were reinstated after line number 2277 (May 1992 onwards). This was to reduce elevator and elevator tab vibration during flight to increase their hinge bearing service life. They have been designed out of the MAX. The CDL says that if any of these vortex generators are not fitted or missing “occasional vertical motions may be felt which appear to be light turbulence These motions are characteristic of this airplane and should not be construed to be associated with Mach buffet. The 737 MAX has an aerodynamically redesigned circular tail cone so does not require any vortex generators.

In the background, sharing the overcast, is Iran Air Boeing 747 freighter EP-ICC and two of the company's 737-200's.

Before the 1979 Iranian Revolution, Iran bought four 747-100 aircraft with air-refueling boom conversions to support its fleet of F-4 Phantoms. For this work these 747’s didn't needed a side cargo door. Only a nose door was sufficient. Before being transfered to Iran Air EP-ICC was one of these tankers. Consequenly she still is missing her side cargo door.

The bright white Iran Air Boeing 747-2J9 freighter, EP-ICC, stands out against the gloom of a September day at Theran - Merabad in 2006.

Once, very powerful Pratt & Whitney JT9D's overlooking a ramp full of geriatric giants.

During the 80's EP-ICC was a frequent visitor to my homebase airport, Amsterdam Schiphol Airport.

The billboard Iran Air Cargo insignia emblazoned across the forward side of the Iran Air 747 freighter makes her a distinctive sight on the ramp.

The Pratt & Whitney JT9D engine was the major powerplant for the early 747's.

Critical areas that are prone to excessive corrosion include areas below the galleys, doorways, lavatories, cargo compartment subfloors, inside external fairings and the bilges which are all treated at four-year intervals. Landing gear wheel wells and wing spars are treated yearly.

The service life of this 'tired iron' seems over.

A supposedly anonymous Fokker F-27 was found on a bright morning in September 2006 at Merabad airport, but the registration SN-4101 identifies her as one of the Iran Revolutionary Guard fleet out of Theran.

Fokker F-27-600 SN-4101 marooned in a corner of the airfield at Theran - Merabad, in 2006.

This Fokker F-27-600 was delivered to Iran Aseman Airlines in 1983. The registration was EP-ANA. In 1990 during flight from Tehran to Ramsar, after landing in destination airport, the Fokker ran off the runway and was damaged. A few months later she was repaired and transferred to the "Iran Aviation Industries Co". Later on she became part of the Iran Revolutionary Guard fleet of aircraft. The -600 was in service until 2004, then due to mechanical problems she was grounded and placed in Tehran's Aerospace Exhibition Center.

The bright white uniform of Iran Revolutionary Guard Fokker F-27-600 caught by the camera on a tranquil sun-drenched day at Theran - Merabad.

Fokker F-27-600 SN-4101 still manages to look majestic despite being parked amid the aeronautical trash at Theran - Merabad in Sept. 2006.

Her bright white uniform is still gleaming in the strong summer sunlight.

Ultra violet light is the culprit, bleaching out colors. Airplanes are no different and high altitude flight, such as that performed by this Iran Navy Aero Commander 500, accelerated the fading process.

Heads and tails ; a Boeing 737-200 sticks its nose into a gaggle of a Fokker F-27-600.