Quebec Bush-planes 2016

Along Riviere St. Maurice

By Jan Koppen

Trois Rivieres

C-GTLD and G-GJVN are both Hawker Siddley 748's.

Hawker Siddley HS.748-2A C-GTLD was delivered new to First Air in 1978 and remained with this Canadian operator until being ferried to Trois Riviered in October 2007 for storage.

Hawker Siddley HS.748-2A C-GJVN was also delivered new to First Air. She also operated for 'the Airline of the North' until her retirement in April 2007. With 62.541 flying hours she is the highest time 748.

Hawker Siddley HS.748-2A C-GJVN was also delivered new to First Air. She also operated for 'the Airline of the North' until her retirement in April 2007. With 62.541 flying hours she is the highest time 748.

|

C-GTVO is a 1982 built Boeing 737-200.

Boeing 737-219C(A) C-GTVO left the Renton production-line in November 1982 on delivery to Air New Zealand Cargo. After 19 years of wearing the ubiquitous koru logo she was sold to Airwork Cargo in March 2001 and resprayed in the striking yellow livery. In October 2012 she was exported to Canada by J. & L. Aircraft Leasing who leased this baby Boeing to Starlink Aviation. She has been stored at Trois Rivieres, Quebec for some time. |

After a good night rest, I put 'the General" into drive and started trying to find the hide away waterdrome of Hydravion along the Saint-Maurice River, near Saint-Étienne-des-Grès. Eventually I succeeded but it wasn't easy.

Saint-Etienne-des-Gres

This must be one of the world's most picturesque water aerodrome - especially on a clear afternoon like this.

|

Saint-Étienne-des-Grès/Hydravion Adventure Water Aerodrome is located 2.5 nautical miles (4.6 km; 2.9 mi) southeast of Saint-Boniface, Quebec, Canada on the Saint-Maurice River.

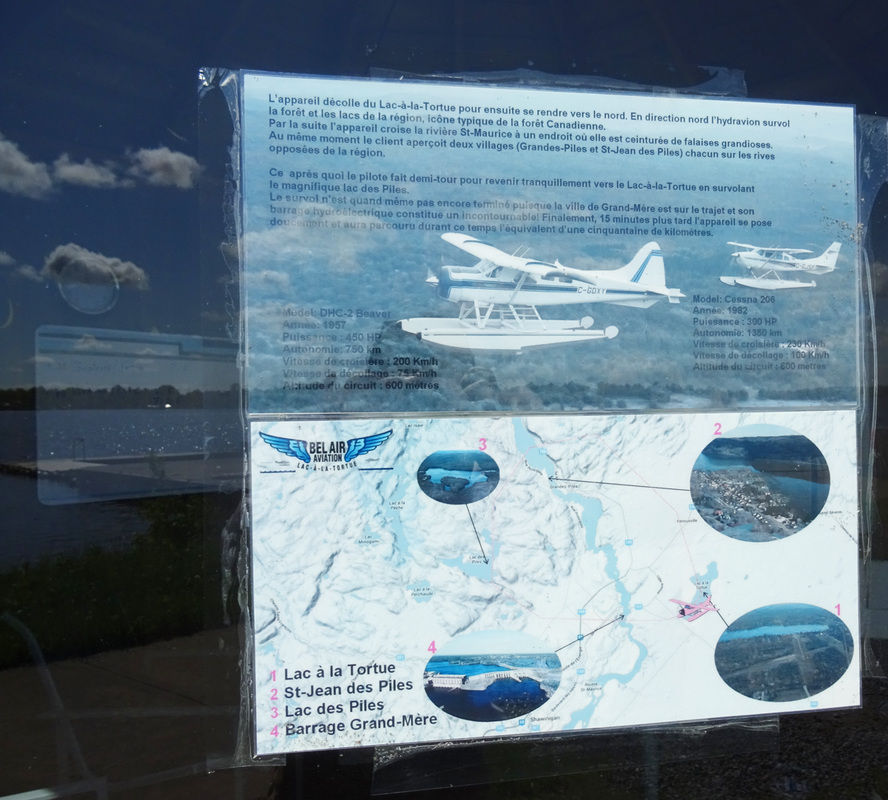

Hydravion Aventure is an airline whose unique flotilla of amphibious seaplanes ranges from the legendary De Havilland Beaver to modern Cessnas, providing you with transport from any international airport to the docks of some of Québec’s finest forest lodges. |

|

C-FJAB. This aircraft left the Downsview factory in 1956 for delivery to Fecteau Transport. After many years of faithful service with Arthur Feteau she changed hands several times and worked for famous operators like Propair, Air Saguenay and Georgian Bay Airways Ltd., before she finally became part of the Hydravion Adventure fleet in 2007.

|

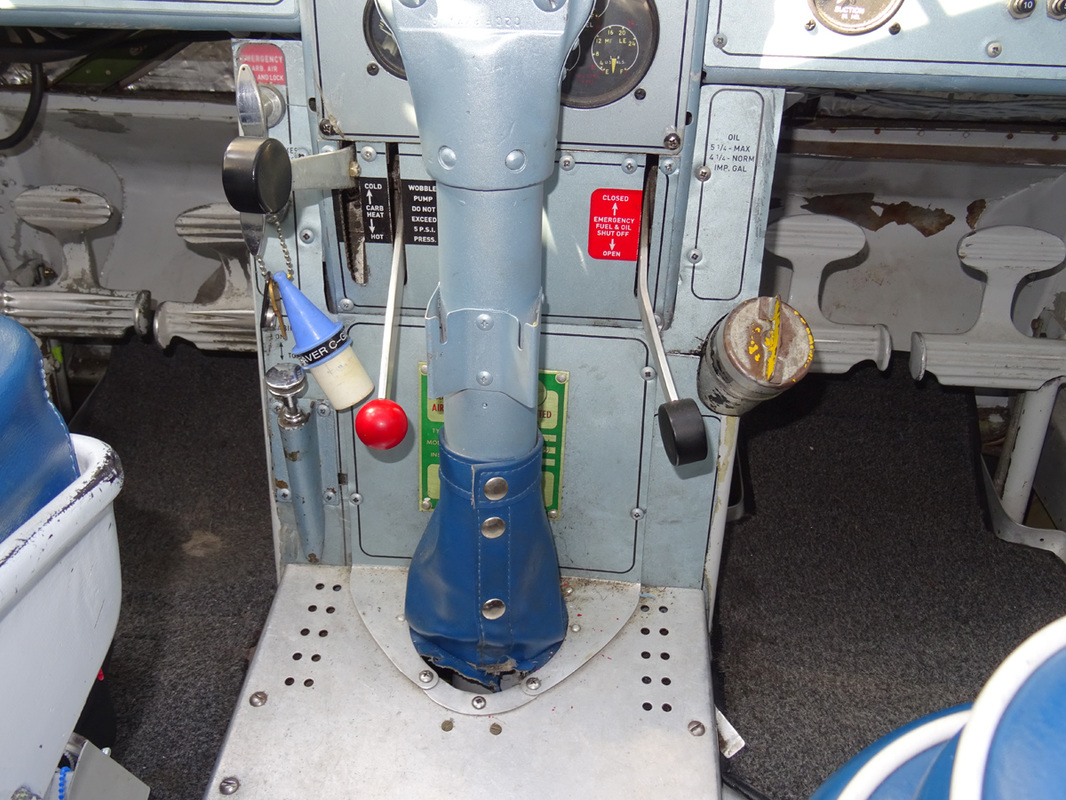

The engine control quadrants are located at the top of the pedestal. Friction control knobs, one below each control lever, increase lever friction when rotated clockwise.

The throttle lever movers in a quadrant marked OPEN and CLOSED. The lever is connected to the throttle valve by means of pus-rods and torque-tube linkage.

The mixture lever moves in a quadrant marked as follows: AUTO LEAN – AUTO RICH – FULL RICH – FULL LEAN – IDLE CUF-OFF. The lever is connected to the carburetor by means of push-rods and torque-tube linkage.

The throttle lever movers in a quadrant marked OPEN and CLOSED. The lever is connected to the throttle valve by means of pus-rods and torque-tube linkage.

The mixture lever moves in a quadrant marked as follows: AUTO LEAN – AUTO RICH – FULL RICH – FULL LEAN – IDLE CUF-OFF. The lever is connected to the carburetor by means of push-rods and torque-tube linkage.

Love the tail art on this plane.

Hydravion Aventure is an airline whose unique flotilla of amphibious seaplanes ranges from the legendary De Havilland Beaver to modern Cessnas, providing you with transport from any international airport to the docks of some of Québec’s finest forest lodges.

|

C-FSGB is a 1965 built Cessna 180H Skywagon.

Six seat high wing light aircraft powered by a 230 hp (172 kW) Continental O-470-L or O-470-R, landplane gross weight 2,800 lb (1,270 kg) and first certified on 17 June 1964. Among the more significant changes of the 1965 Model 180H were:

|

This 180 on straight floats is waiting out for some action.

C-FZXF is a 1967 built Cessna 180H Skywagon.

On this 1967 Model 180H the more following changes were performed:

These all-aluminum floats are rugged, extremely long-lasting, relatively inexpensive, and very easy to repair. I have not yet seen a material which can match aluminum in all these areas, particularly the punishment of rough-water take-offs and landings, and extremes of temperature.

On this 1967 Model 180H the more following changes were performed:

- Pointed propeller spinner increases length 3 inches.

- Extended baggage area.

- Aeroflash rotating beacon.

- Optional auxiliary door on left side.

- Individual center passenger seats.

- Cleveland brakes made standard.

These all-aluminum floats are rugged, extremely long-lasting, relatively inexpensive, and very easy to repair. I have not yet seen a material which can match aluminum in all these areas, particularly the punishment of rough-water take-offs and landings, and extremes of temperature.

Awesome 2014 Wagaero Sport Trainer set for a splash & go.

|

C-FZIA/2367 looks like a Piper Cub but this is not the case. It is a 2014 built Wagaero Sport Trainer which is owner by Alain Priem of Saint-Etienne des Gres, Quebec. The Sport Trainer is a replica of the Piper J-3 Cub but with nowadays goodies.

The Wag-Aero CUBy is a replica of the Piper J-3, designed by Dick Wagner and marketed by Wag-Aero of Lyons, Wisconsin as plans or in kit form. The aircraft is currently marketed under the name Wag-Aero Sport Trainer. The Sport Trainer is an original CUBy but renamed and powered by engines in the recommended range of 65 to 100 hp (48 to 75 kW). |

|

Watch the show!

Wagaero Sport Trainer C-FZIA working it's way up off the waters of Saint-Maurice River. Enjoy. |

|

Prestine Piper Cub J3C-65 CF-SVT floatplane is seen here at Hydravion Adventure Water Aerodrome which is located in the vecinety of Saint-Étienne-des-Grès.

According the archives, the Cub rolled-off the Lock Haven, Pennsylvania, production-line in 1939. The J3L-65 variant was equipped with a Lycoming O-145-B1, B2 or B3 of 65 hp (48 kW).

According the archives, the Cub rolled-off the Lock Haven, Pennsylvania, production-line in 1939. The J3L-65 variant was equipped with a Lycoming O-145-B1, B2 or B3 of 65 hp (48 kW).

|

The Piper J-3 Cub is an American light aircraft that was built between 1937 and 1947 by Piper Aircraft. The aircraft has a simple, lightweight design which gives it good low speed handling properties and short field performance. The Cub is one of the best known light aircraft of all time. The Cub's simplicity, affordability and popularity — as well as its large production numbers, with nearly 20,000 built in the United States — invokes comparisons to the Ford Model T automobile.

The Cub was originally intended as a trainer, and saw great popularity in this role and as a general aviation aircraft. Due to its performance, it was well suited a variety of military uses such as reconnaissance, liaison and ground control, and was produced in large numbers during the Second World War as the L-4 Grasshopper. Large numbers of Cubs are still flying today. Notably Cubs are highly prized as bush aircraft. The Cub is a high-wing strut-braced monoplane with a large area rectangular wing. It is powered by an air-cooled piston engine driving a fixed pitch propeller. Its fuselage is a welded steel frame covered in fabric, seating two people in tandem. The aircraft's standard chrome yellow paint has come to be known as "Cub Yellow". |

|

"I put 'the General' into drive for the short journey to Lac-à-la-Tortue Airport/Waterdrome along the banks of Lac-à-la-Tortue".

Lac-a-la-Tortue

|

Lac-à-la-Tortue Airport is located 2.6 nautical miles (4.8 km; 3.0 mi) east of Lac-à-la-Tortue, Quebec, Canada.

In June of 1919, a postal airplane named "La Vigilance" landed on the quiet waters of Lac-à-la-Tortue. Shortly after this historical event, the site became Canada’s first seaplane base. In the decades that followed, some of Canada's early aviation pionneers as well as several airlines operated from the base. More than 80 years later, well situated in central Québec, Lac-à-la-Tortue remains an important aviation center. In the spring of 1965, Bel Air Laurentien Aviation was created from the merger of Laurentian Aircraft Overhauled & Sales Ltd and Bel-Air Services Inc. In 1968, Bel Air became a Cessna dealer. The following year, to meet the needs of its growing number of customers, the company built two private runways. Today, Bel Air Aviation is the most important maintenance and repair facility for light aircraft and seaplanes in Eastern Canada. They offer a wide range of services including purchase and sales of aircraft, parts and components. They are dealers for Lycoming, Continental, and Pratt & Whitney aircraft engines. Their facility is capable in accomplishing everything from small alterations to major structural repairs and they maintain a full range of Cessna parts and much more. Fuel servicing is also available at the airbase and seaplane base. |

Close up view of a Bel-Air's DHC-2 Beaver being ready for a scenic flight from Lac-à-la-Tortue floatplane base.

|

C-GDXY, came off the production line in June 1957 for delivery to the U.S. Army. This sturdy Beaver was one of the many which were stored during the mid seventies, at Davis Monthan. She came back to Canada in 1976 and works with Bel-Air Laurentien Aviation Inc., Lac-à-la-Tortue since 2009.

Note the nose extension, it is longer than most. This is the DHC-2 Holmes Extended Engine Mount. Due to the original aircraft’s design, most Beavers flying today at gross weight are far from legal when it comes to the aft C of G. All the baggage extensions and gross weight increases have only made this worse. The Extended Engine Mount moves 917 lbs. nearly ten inches forward of its original position, putting the empty weight C of G at the forward limit so that all loading has a chance to stay within limits. It stands to reason that a loaded Beaver, which is normally wallowing around, dragging its ass, would benefit from having the C of G moved forward. From the maintenance perspective, anyone who has tried to change a mag or starter, or adjust points or find an oil leak will love this modification. Also flight-testing shows a number of advantages of the Extended Engine Mount; -The time from throttle application to the aircraft on the step appears to be cut in half, the aircraft climbs faster, an increase in cruise airspeed is apparent and there is no need for cruise flaps.

Note the nose extension, it is longer than most. This is the DHC-2 Holmes Extended Engine Mount. Due to the original aircraft’s design, most Beavers flying today at gross weight are far from legal when it comes to the aft C of G. All the baggage extensions and gross weight increases have only made this worse. The Extended Engine Mount moves 917 lbs. nearly ten inches forward of its original position, putting the empty weight C of G at the forward limit so that all loading has a chance to stay within limits. It stands to reason that a loaded Beaver, which is normally wallowing around, dragging its ass, would benefit from having the C of G moved forward. From the maintenance perspective, anyone who has tried to change a mag or starter, or adjust points or find an oil leak will love this modification. Also flight-testing shows a number of advantages of the Extended Engine Mount; -The time from throttle application to the aircraft on the step appears to be cut in half, the aircraft climbs faster, an increase in cruise airspeed is apparent and there is no need for cruise flaps.

|

Watch the show!

Bel-Air's DHC-2 Beaver C-GDXY and their two Cessna 206's operating scenic flights from their Lac-à-la-Tortue floatplane base. Enjoy. |

|

A shock-mounted flight instrument panel is provided for the pilot and incorporates and altimeter, turn-and-bank indicator, rate-of-climb indicator, air speed indicator, directional gyro and artificial horizon. The airspeed indicator, altimeter and the rate-of-climb indicator, are operated by the pitot static system, The static opening is incorporated in the left-hand side of the rear fuselage. The directional gyro, artificial horizon and turn-and-bank indicator, are operated by the vacuum system. A vacuum gauge on the right of the electrical switch panel indicates the vacuum in In.Hg. being applied to the instruments.

The wing flaps are of the slotted type and extend from the wing roots to the inboard ends of the ailerons which also droop in conjunction with the flap movements. The flaps are operated by an actuating cylinder located in the fuselage at the left-hand wing root. Hydraulic fluid is supplied to the actuating cylinder by a handpump, under the pilot’s seat. This handpump has an integral reservoir, a selector valve and a relief valve. The relief valve is set at 1,000 psi.

The wing flap hand pump lever is at the right-hand side of the pilot’s seat and is operated in a fore-and-aft direction. The wing flaps selector lever is located on the right-hand side of the pilot’s seat. It has two marked positions, UP and DOWN. Intermediate positions of the wing flaps are selected by moving the selector lever to UP or DOWN then pumping the wing flaps with the hand pump lever to the desired position, as shown on the wing flaps indicator. If the flaps are in any lowered position, it is essential that the selector lever is retained in the DOWN position. When the flaps are retracted, the selector lever must be retained in the UP position. Once the selector lever is set to DOWN and the flaps are pumped to the desired position, the selector lever must not be moved until it is desired to change the flap position.

A wing flaps position indicator is situated above the flight instrument panel. It is marked FULL FLAP, LANDING, TAKE-OFF, CLIMB and CRUISE. FULL FLAP is only required for emergency landing in very restricted areas.

The wing flap hand pump lever is at the right-hand side of the pilot’s seat and is operated in a fore-and-aft direction. The wing flaps selector lever is located on the right-hand side of the pilot’s seat. It has two marked positions, UP and DOWN. Intermediate positions of the wing flaps are selected by moving the selector lever to UP or DOWN then pumping the wing flaps with the hand pump lever to the desired position, as shown on the wing flaps indicator. If the flaps are in any lowered position, it is essential that the selector lever is retained in the DOWN position. When the flaps are retracted, the selector lever must be retained in the UP position. Once the selector lever is set to DOWN and the flaps are pumped to the desired position, the selector lever must not be moved until it is desired to change the flap position.

A wing flaps position indicator is situated above the flight instrument panel. It is marked FULL FLAP, LANDING, TAKE-OFF, CLIMB and CRUISE. FULL FLAP is only required for emergency landing in very restricted areas.

The carburetor heat control lever is located below the engine instrument panel and is cable-connected to a gate valve in the carburetor air intake duct. When the lever is selected up to the COLD position, cold ram air enters the carburetor through the air intake duct. As the lever is moved down towards the HOT position, the gate valve progressively closes the cold air intake while opening the warm air duct. This second duct allows heated air, from inside a heat exchanger muff surrounding a section of the engine exhaust collector, to mix with the cold ram air before delivery to the carburetor. Intermediate position of the lever between fully up and fully down will therefore give varying degrees of carburetor air intake temperature. With the lever in the HOT position the ram air intake is fully closed and heated air only is ducted to the carburetor. For operation in desert areas a dust filter for the ram air intake can be installed.

Electrical DC energy is supplied by a 50 amp 28-30 volt generator in conjunction with a 24 volt 17 amp/hr. battery. The generator output is regulated by a carbon pile voltage regulator. A reverse-current relay is used to protect the generator when is not charging.

A volt-ammeter, located in the electrical switch panel, indicates the amperage of the generator supply. The voltage of the generator supply is indicated when charging by pressing the stud at the lower left of the instrument. When the generator is not operating, the battery voltage only will be indicated.

A volt-ammeter, located in the electrical switch panel, indicates the amperage of the generator supply. The voltage of the generator supply is indicated when charging by pressing the stud at the lower left of the instrument. When the generator is not operating, the battery voltage only will be indicated.

The propeller lever in the engine controls quadrant on the top of the pedestal and sled in a gate marked RPM, DECREASE and INCREASE. It is connected by a push/pull rod linkage to the propeller governor. The governor retains the selected rpm constantly, within the operating range of the propeller, regardless of variations in air loads of flight attitudes. When INCREASE RPM is selected the governor directs oil from its own engine driven pump to the propeller, at pressure, which hydraulically moves the propeller blade, in opposition to the counterweight, to lower angels. When DECREASE RPM is selected the governor allows oil from the propeller to return to the engine sump and the counterweights mover the blade to higher angles.

The fuel transfer selector, for use when wing tip tanks are installed, is located to the left of the pilot, above the cockpit door window. It has four positions marked LH, RH, BOTH and OFF.

C-GPPZ waiting her passengers at Lac-a-la-Tortue.

C-GPPZ is a 1982 built Cessna U206G Stationair. The six-seat Model 206 was introduced as a 1964 model and was built until 1986, when Cessna halted production of its single-engined product line. It was then re-introduced in 1998 and remains in production in 2013. There were many sub-variants, including the U206, P206 all certified to CAR3 standards and later 206H certified to FAR Part 23. The total Model 206 production between 1964 and 2004 was 6,581 aircraft.

The original 1964 model was the U206, powered by a 285 hp (213 kW) Continental IO-520-A. The “U” designation indicated “utility” and this model was equipped with a pilot side door and large clamshell rear door serving the back two rows of seats, allowing easy loading of oversized cargo.

The original 1964 model was the U206, powered by a 285 hp (213 kW) Continental IO-520-A. The “U” designation indicated “utility” and this model was equipped with a pilot side door and large clamshell rear door serving the back two rows of seats, allowing easy loading of oversized cargo.

|

C-GVYR is a Cessna 185 Skywagon II on EDO floats.

The Cessna 185 first appeared in 1961 as an evolutionary follow-on to the popular 180. It's basically a beefed-up 180 with a 260-horsepower fuel-injected Continental IO-470. Adding 30 more horses to the proven design immediately won the attention (and affection) of charter operators needing additional power for floatplanes, high-altitude flight, and heavy hauling. |

Skywagon ... gotta love 'em! C-GBOB is a 1974 Cessna 185F Skywagon II.

On balance, the Cessna 185's offer a good compromise between load- carrying abilities and short-field performance. The Cessna does not offer the same short field performance of Super Cub (and similar aircraft) but they will easily carry four adults. Helio Couriers offer Super Cub-like performance for four adults, but the Couriers are rare, have engines that are expensive to maintain and can be challenging to maintain in general. Thousands of Cessna 180s and 185s were produced and parts availability does not appear to be a matter of great concern for the foreseeable future.

Among the more significant changes of the 1974 Model A185F were:

On balance, the Cessna 185's offer a good compromise between load- carrying abilities and short-field performance. The Cessna does not offer the same short field performance of Super Cub (and similar aircraft) but they will easily carry four adults. Helio Couriers offer Super Cub-like performance for four adults, but the Couriers are rare, have engines that are expensive to maintain and can be challenging to maintain in general. Thousands of Cessna 180s and 185s were produced and parts availability does not appear to be a matter of great concern for the foreseeable future.

Among the more significant changes of the 1974 Model A185F were:

- Optional bubble door windows and lower door panel windows.

- Optional skylights.

- Optional rudder pedal extensions.

- Vertical fin attachment redesigned.

C-GUFJ is a 1976 built Cessna U206F Stationair 6 with a Robertsen STOL kit.

The original 1964 model was the U206, powered by a 285 hp (213 kW) Continental IO-520-A. The “U” designation indicated “utility” and this model was equipped with a pilot side door and large clamshell rear door serving the back two rows of seats, allowing easy loading of oversized cargo.

The original 1964 model was the U206, powered by a 285 hp (213 kW) Continental IO-520-A. The “U” designation indicated “utility” and this model was equipped with a pilot side door and large clamshell rear door serving the back two rows of seats, allowing easy loading of oversized cargo.

The 206 seems to be made for floats, such a beautiful aircraft in this configuration.

From 1964 to 1969 the U206 was known as the “Super Skywagon”. From 1970 it was named the “Stationair”, a contraction of “Station Wagon of the Air”, which is a good description of the aircraft's intended role. Sub-variants were designated U206 to U206G.

Production of all versions of the U206 was halted in 1986 when Cessna stopped manufacturing all piston-engined aircraft. A total of 5,208 U206s had been produced.

Production of all versions of the U206 was halted in 1986 when Cessna stopped manufacturing all piston-engined aircraft. A total of 5,208 U206s had been produced.

C-GCMH is a Cessna 182 updated with a Sportsman STOL kit and is sitting on top of old-fashion Edo floats.

Nosewheels became the rage during the 1950s, and it was no surprise when, in 1956, Cessna substituted one for the 180’s tailwheel. The result was the Cessna 182, which cruised and climbed a bit slower as a result of the added drag. Today’s Skylane evolved to be much improved over the original.

Nosewheels became the rage during the 1950s, and it was no surprise when, in 1956, Cessna substituted one for the 180’s tailwheel. The result was the Cessna 182, which cruised and climbed a bit slower as a result of the added drag. Today’s Skylane evolved to be much improved over the original.

Lac-a-la-Tortue airport

C-GJSF is a Cessna U206F Stationair.

Production of all versions of the U206 was halted in 1986 when Cessna stopped manufacturing all piston-engined aircraft. A total of 5,208 U206s had been produced.

Production of all versions of the U206 was halted in 1986 when Cessna stopped manufacturing all piston-engined aircraft. A total of 5,208 U206s had been produced.

|

ETE, a privately operated Beaver on Wipline 6000 amphibious floats photographed in the Bel-Aviation hangar at Lac-a-la-Tortue Airport (30km north of Trois Rivieres, Quebec).

C-FETE which manufactured in 1958 for delivery to the Roman Catholic Church started her career with registration CF-OMI (Oblate of Mary Immaculate). Eventually it went to North Coast Air Services of Prince Rupert, BC. After being seriously damaged she was rebuilt by Pacific Salvage in 1986. From 1986 she served with the following operators; - Odessy Air, Ontario Inc. and Four Seasons Aviation. In 2010 Louis Giguere of Saint-Jerome, Quebec became the proud owner of this pristine Beaver. Note; - The three-bladed Hartzell propeller offers a quieter ride than the longer two-bladed prop and with its smaller diameter, sustains less damage from water spray. |

|

When floats are built with wheel landing gears built into them they are called “amphibious” or just “amphibs”. Hydraulic wheels in the nose and underneath the floats allow the plane to land on both land and, (when retracted), water. While amphibious floats give great versatility to an airplane as far as landing options, there is a significant trade-off. The added weight of the wheels means the plane can carry less ….. referred to as “useful load”. Performance of the aircraft may be affected, and the price and maintenance of wheel floats is significant also!

|

C-FRGW is a Cessna 172I Skyhawk.

The 1968-built Cessna 172I introduced the Lycoming O-320-E2D engine of 150 hp (112 kW).

The 1968 model marked the beginning of the Lycoming-powered 172s. The familiar 172 needed to be re-engined because Cessna had cancelled its contract with Continental for their venerable O-300 6-cyl engine of 145 hp (108 kW).

The "I" model was introduced with a Lycoming O-320-E2D engine of 150 hp (112 kW), an increase of 5 hp (3.7 kW) over the Continental powerplant. The increased power resulted in an increase in optimal cruise from 130 mph (209 km/h) TAS to 131 mph (211 km/h) TAS (true airspeed). There was no change in the sea level rate of climb at 645 ft (197 m) per minute.

The 172I also introduced the first standard "T" instrument arrangement. The 172I saw an increase in production to record levels with 1,206 built.

The 1968-built Cessna 172I introduced the Lycoming O-320-E2D engine of 150 hp (112 kW).

The 1968 model marked the beginning of the Lycoming-powered 172s. The familiar 172 needed to be re-engined because Cessna had cancelled its contract with Continental for their venerable O-300 6-cyl engine of 145 hp (108 kW).

The "I" model was introduced with a Lycoming O-320-E2D engine of 150 hp (112 kW), an increase of 5 hp (3.7 kW) over the Continental powerplant. The increased power resulted in an increase in optimal cruise from 130 mph (209 km/h) TAS to 131 mph (211 km/h) TAS (true airspeed). There was no change in the sea level rate of climb at 645 ft (197 m) per minute.

The 172I also introduced the first standard "T" instrument arrangement. The 172I saw an increase in production to record levels with 1,206 built.

|

Those big bush wheels!

C-FWPC is a 2000 built Christen-A1B of Avia Aircraft Husky. The rugged, reliable Husky taildragger was designed for people who’d rather fly a real airplane. It’s ideal for landings on grass, glaciers, river beds, rivers, meadows, roads, frozen lakes, unfrozen lakes, sand beaches, sand bars, aircraft carriers and pick-up trucks. It’s the perfect solution for serious fly fishing, for hauling medical supplies, pipeline patrol, cattle counting, fish spotting, gendarme work, backpacking, mountain leaping, safaris, photography and exciting weekend adventures of all types. |

Gotta love the Husky design paint scheme of this plane.

Manufactured in 1956, C-FMPR, came off the line at de Havilland and was delivered to the Royal Canadian Mounted Police, Air Division. After her long career with the RCMP, she served numerous bush plane operators mainly in Quebec, Canada. Since March 2016 ‘Papa Romeo’ works for Seapass Aviation Inc.

C-FMPR still wears Les Motels de L’Energie Inc. titles. A company she worked for from 2002 until 2014.

Fate struck a blow when it crashed on August 30, 1984. The aircraft was equipped with floats, and left Squaw Lake (QC) to conduct a flight under visual flight rules (VFR) up to Wabush, Sept-Iles (QC). The ceiling was falling and the visibility decreasing in fog. To maintain VFR, the pilot descended below the top of the hills and flew along the lakes along its route. Forty miles north of Sept-Iles, the aircraft struck trees on rising terrain and came to rest in a wooded area. The pilot had checked the weather before the flight. The meteorological conditions at Sept-Iles were below VFR minimums, but they were set to improve to become VFR marginal at the time of arrival at the planned destination. The approach of a cold front made the air mass in the region unstable and after the forecast, the ceiling descended to 500 feet above the ground and the visibility was to be limited to a mile in thunderstorms. The pilot was advised of the latest weather conditions for Sept-Iles, which indicated an improvement at arrival time. Meteorological conditions provided for the area were such that the pilot could have expected to encounter poor weather conditions below VFR minimums. With this knowledge, the pilot continued the flight to the moment he was forced to fly at a very low altitude to stay VFR. He could not see the rising terrain before it arrived because of the poor visibility and the aircraft encountered trees. When the weather started to deteriorated, the pilot could have turned around and landed VFR in a suitable location or climbed to height and filed an IFR flight plan.

C-FMPR still wears Les Motels de L’Energie Inc. titles. A company she worked for from 2002 until 2014.

Fate struck a blow when it crashed on August 30, 1984. The aircraft was equipped with floats, and left Squaw Lake (QC) to conduct a flight under visual flight rules (VFR) up to Wabush, Sept-Iles (QC). The ceiling was falling and the visibility decreasing in fog. To maintain VFR, the pilot descended below the top of the hills and flew along the lakes along its route. Forty miles north of Sept-Iles, the aircraft struck trees on rising terrain and came to rest in a wooded area. The pilot had checked the weather before the flight. The meteorological conditions at Sept-Iles were below VFR minimums, but they were set to improve to become VFR marginal at the time of arrival at the planned destination. The approach of a cold front made the air mass in the region unstable and after the forecast, the ceiling descended to 500 feet above the ground and the visibility was to be limited to a mile in thunderstorms. The pilot was advised of the latest weather conditions for Sept-Iles, which indicated an improvement at arrival time. Meteorological conditions provided for the area were such that the pilot could have expected to encounter poor weather conditions below VFR minimums. With this knowledge, the pilot continued the flight to the moment he was forced to fly at a very low altitude to stay VFR. He could not see the rising terrain before it arrived because of the poor visibility and the aircraft encountered trees. When the weather started to deteriorated, the pilot could have turned around and landed VFR in a suitable location or climbed to height and filed an IFR flight plan.

|

The lower air induction system consists of an air scoop in the lower engine cowling (later the air scoop could be replaced on-top of the cowling) feeding unfiltered air through a duct and into the carburetor. This system can be equipped with a hinged, dry air filter mechanically connected to a carburetor air filter control installed above and to the right of the engine controls quadrant. The control is marked CARB AIR, IN-RAM, OUT-FILTER and arrowed counterclockwise with TURN TO UNLOCK. At the RAM position the filter lies flush with the bottom of the air scoop and allows unfiltered ram air to enter the carburetor. At the FILTER position, the forward end of the filter is raised so that air entering the scoop must pass through the filter before entering the carburetor. The control must be turned clockwise to lock in either position. Under no circumstance must the CARB AIR control remain in any intermediate position between IN-RAM and OUT-FILTER. In and intermediate position the filter will cause a blockage in the induction system. The effect of the filter is to reduce the 5,000 foot critical altitude by approximately 800 feet. Below this new critical altitude there is no loss in engine power, while above this altitude the power loss is small. The engine may be started with the CARB AIR control in the RAM position to avoid damage in the filter in case of back-fires. Immediately after starting the engine, in areas wherever there is a possibility of dust, sand or dirt entering the intake, the control should be moved to and remain at FILTER position for all ground running, taxiing and take-off, and during flight if necessary. Take-off from a short field, at or above the new critical altitude, should be made with the CARB AIR control at RAM position, Before landing in dusty or sandy areas, the control must be selected to FILTER and remain in this position while the aircraft is on the ground, except when starting the engine as previously explained.

|

C-FEWV is a 1972 built Cessna 172L Skyhawk of Aero Ateliers.

The 172L, sold during 1971 and 1972, replaced the main landing gear legs (which were originally flat spring steel) with tapered, tubular steel gear legs. The new gear had a width that was increased by 12 in (30 cm). The new tubular gear was lighter, but required aerodynamic fairings to maintain the same speed and climb performance as experienced with the flat steel design. The "L" also had a plastic fairing between the dorsal fin and vertical fin to introduce a greater family resemblance to the 182's vertical fin.

The 1971 model sold for US$13,425 in the 172 version and US$14,995 in the Skyhawk version. 827 172Ls were sold in 1971 and 984 in 1972.

The 172L, sold during 1971 and 1972, replaced the main landing gear legs (which were originally flat spring steel) with tapered, tubular steel gear legs. The new gear had a width that was increased by 12 in (30 cm). The new tubular gear was lighter, but required aerodynamic fairings to maintain the same speed and climb performance as experienced with the flat steel design. The "L" also had a plastic fairing between the dorsal fin and vertical fin to introduce a greater family resemblance to the 182's vertical fin.

The 1971 model sold for US$13,425 in the 172 version and US$14,995 in the Skyhawk version. 827 172Ls were sold in 1971 and 984 in 1972.

|

Guy-Paul Mongrain started working as an aircraft engine mechanic in 1972. The Aero Atelier journey begun in 1980 when Guy-Paul decided to start his own company by purchasing a small garage in his home town of Hérouxville, QC. Remain small was the initial objective, in order to keep quality a top-priority. However, word of mouth quickly propelled Aero Atelier to the rank of key player in the piston-powered aircraft engine industry in Quebec. The party that had started as a two-men show grew to a bigger team over the years and found that personalized customer service and high levels of quality is not an option, it’s a lifestyle. In 2003, Aero Atelier decided to invest in growth by purchasing Aero Moteur, an engine shop located in Lac-à-la-Tortue. |

An immaculate example of an early production model Cessna 172.

C-FBYS is a Cessna 172K and sits on top of aluminium Edo floats. The 1969 saw the "K" model. The 1969 172K had a redesigned tailfin cap and reshaped rear windows. Optional long-range 52 US gal (197 l) wing fuel tanks were offered. The rear windows were slightly enlarged by 16 square inches (103 cm2). The 1969 model sold for US$12,500 for the 172 and US$13,995 for the Skyhawk, with 1,170 made.

The 1970 model was still called the 172K, but sported fiberglass, downward-shaped, conical wing tips. Fully articulated seats were offered as well. Production in 1970 was 759 units.

C-FBYS is a Cessna 172K and sits on top of aluminium Edo floats. The 1969 saw the "K" model. The 1969 172K had a redesigned tailfin cap and reshaped rear windows. Optional long-range 52 US gal (197 l) wing fuel tanks were offered. The rear windows were slightly enlarged by 16 square inches (103 cm2). The 1969 model sold for US$12,500 for the 172 and US$13,995 for the Skyhawk, with 1,170 made.

The 1970 model was still called the 172K, but sported fiberglass, downward-shaped, conical wing tips. Fully articulated seats were offered as well. Production in 1970 was 759 units.

C-FRFM is a 1980 built Cessna TU206E Stationair 6 II and sits on Wipline floats.

The original 1964 model was the U206, powered by a 285 hp (213 kW) Continental IO-520-A. There was a TU206 turbocharged version powered by the Continental TSIO-520-C engine producing 285 hp (213 kW). After 1967 the turbo TU206 was powered by a TSIO-520-F of 300 hp (220 kW). The extra 15 hp (11 kW) was obtained by turning the engine at a higher rpm, and was only allowed for five minutes. Due to the large propeller diameter, the additional engine speed meant that the propeller tips were pushed to transonic speeds, which required much more power.

Wipaire is an American manufacturing and repair facility. It was founded shortly after World War II by Ben Wiplinger, a veteran of the United States Army Air Forces. He returned to his native Minnesota and set up shop at South St. Paul Airport to convert surplus military aircraft (usually transport types; sometimes bombers) into civilian executive aircraft.

Wiplinger was an avid floatplane pilot, and he was familiar with the dominant line of light-aircraft floats of the era, EDO. He sought an EDO dealership, but was turned down. At that, he determined to fabricate his own line of aircraft floats, and that activity soon became the company's main focus. By 2013 the company had delivered over 2000 sets of floats, ranging in capacity from Cubs to Twin Otters. However, along with the manufacture and installation of floats, the company gradually returned to its original role of aircraft servicing, maintenance, modifications, painting and interior completions.

Until 2013 the company was based entirely in Minnesota. In late January 2013, it opened a floatplane service and repair facility at Leesburg International Airport in Lake County, Florida.

The original 1964 model was the U206, powered by a 285 hp (213 kW) Continental IO-520-A. There was a TU206 turbocharged version powered by the Continental TSIO-520-C engine producing 285 hp (213 kW). After 1967 the turbo TU206 was powered by a TSIO-520-F of 300 hp (220 kW). The extra 15 hp (11 kW) was obtained by turning the engine at a higher rpm, and was only allowed for five minutes. Due to the large propeller diameter, the additional engine speed meant that the propeller tips were pushed to transonic speeds, which required much more power.

Wipaire is an American manufacturing and repair facility. It was founded shortly after World War II by Ben Wiplinger, a veteran of the United States Army Air Forces. He returned to his native Minnesota and set up shop at South St. Paul Airport to convert surplus military aircraft (usually transport types; sometimes bombers) into civilian executive aircraft.

Wiplinger was an avid floatplane pilot, and he was familiar with the dominant line of light-aircraft floats of the era, EDO. He sought an EDO dealership, but was turned down. At that, he determined to fabricate his own line of aircraft floats, and that activity soon became the company's main focus. By 2013 the company had delivered over 2000 sets of floats, ranging in capacity from Cubs to Twin Otters. However, along with the manufacture and installation of floats, the company gradually returned to its original role of aircraft servicing, maintenance, modifications, painting and interior completions.

Until 2013 the company was based entirely in Minnesota. In late January 2013, it opened a floatplane service and repair facility at Leesburg International Airport in Lake County, Florida.

Old, older, oldest.....C-FNQZ is a 1961 built Cessna 185 Skywagon. This Cessna was 55-years old during my visit.

The 1961 Model 185 Skywagon was introduced, similar to the 180. It featured a 260hp Continental fuel injected IO-470-F. Compared to the 1961 180, the 185 had stronger firewall, landing gear and axles. The interior was extended and a third side window was added. Seating was for six. A long dorsal fin from the vertical stabilizer was the main visible difference from the 180. Fuel capacity was 65 gallons with 84 gallons optional. It was first certified on 31 January 1961.

Although many Skywagons are equipped with a three-blade prop, most floatplane operators opt for the 88-inch two-blade propeller; its greater disk area provides more thrust for pulling a heavily laden floatplane out of the water. But the blat of those long, supersonic prop tips on takeoff is downright obnoxious. 84-inch three-blade prop, which became standard in the last years of production, is quieter, although it still draws a lot of attention on take-off.

The 1961 Model 185 Skywagon was introduced, similar to the 180. It featured a 260hp Continental fuel injected IO-470-F. Compared to the 1961 180, the 185 had stronger firewall, landing gear and axles. The interior was extended and a third side window was added. Seating was for six. A long dorsal fin from the vertical stabilizer was the main visible difference from the 180. Fuel capacity was 65 gallons with 84 gallons optional. It was first certified on 31 January 1961.

Although many Skywagons are equipped with a three-blade prop, most floatplane operators opt for the 88-inch two-blade propeller; its greater disk area provides more thrust for pulling a heavily laden floatplane out of the water. But the blat of those long, supersonic prop tips on takeoff is downright obnoxious. 84-inch three-blade prop, which became standard in the last years of production, is quieter, although it still draws a lot of attention on take-off.

|

Continental 10-550 hp powered C-FQXF is a 1966 built Cessna U206A with DL.JMC marks. The initials JMC are of the owner

Jean-Marie Chabot. The Cessna 205 was the forerunner of the 206 and she was introduced late in 1962 as a 1963. The six-seat aircraft was essentially a Cessna 210 with fixed landing gear and with changes to the crew and passenger door arrangement, being officially designated by Cessna as a "Model 210-5". The 205 retained the early 210’s engine cowling bulge, originally where the 210 stowed its nosewheel on retraction. This distinctive cowling was made more streamlined on the later Cessna 206s, but not on this one. The bulge on the cowling is clearly visible. |

|

C-GUMS is a Cessna 172M which sits on top of Baumann floats.

In 1976, Cessna stopped marketing the aircraft as the 172 and began exclusively using the "Skyhawk" designation. This model year also saw a redesigned instrument panel to hold more avionics. Among other changes, the fuel and other small gauges are relocated to the left side for improved pilot readability compared with the earlier 172 panel designs. Total production of "M" models was 7306 over the four years it was manufactured. |

|

C-GUFS is a Cessna U206F Stationair 6 II with a Robertsen STOL.

What do you get if you stretch a 182 and put two more seats in it? Well when Cessna did it they got the 205 which soon became the 206 and which sometime later, became a plane that can be heard all over bush country. 206s are not the ideal bush plane (they're a little underpowered for as large as they are) and they have the bush hating tri-gear. Even though the 206 does not match the ideal design for a bush plane, it is common in bush country because it does so many things so well and it lacks any real competition. |

|

C-FPRR is a Cessna 172E Skyhawk.

The 172E was the 1964 model. The electrical fuses were replaced with circuit breakers. Gross weight was increased to 2,300 lb (1,043 kg), where it would stay until the 172P. The 172E also featured a redesigned instrument panel. 1,401 172Es were built that year as production continued to increase. |

C-FRYI is a 1965 built Cessna 180H Skywagon II.

Cessna began production of the 180 in 1953 as a more powerful and stout version of its 170 model. Both aircraft featured conventional landing gear and both were eventually fitted with tri-cycle landing gear (becoming the 172 and 182 respectively). 180s were factory-equipped with Continental 0-470 engines intially of 225 hp. Modifications allow installation of 300 hp engines.

The Cessna 180H is a six seat high wing light aircraft powered by a 230 hp (172 kW) Continental O-470-L or O-470-R and was first certified on 17 June 1964.

Among the more significant changes of the 1965 Model 180H were:

Cessna began production of the 180 in 1953 as a more powerful and stout version of its 170 model. Both aircraft featured conventional landing gear and both were eventually fitted with tri-cycle landing gear (becoming the 172 and 182 respectively). 180s were factory-equipped with Continental 0-470 engines intially of 225 hp. Modifications allow installation of 300 hp engines.

The Cessna 180H is a six seat high wing light aircraft powered by a 230 hp (172 kW) Continental O-470-L or O-470-R and was first certified on 17 June 1964.

Among the more significant changes of the 1965 Model 180H were:

- Cessna 182 firewall was used, making the 180 and 185 airframes identical.

- Redesigned instrument panel to accommodate center stack radios..

- Improved fuel strainer.

- Integrated engine instrument cluster.

- Redesigned doors on engine cowl.

C-FUQC is a 1966 built Cessna 180H.

The 180 and 185 are very similar in appearance, but the 185 has a larger dorsal fin attached to its vertical surface (although some 180s were produced with the larger fins and others have been modified to its specifications). Both aircraft are constructed of 2024-T3 Alcad aluminum using a semi-monocoque design with rivet fasteners. While the design was produced easily on an assembly line, the exact construction of the 180 and 185 would likely make kit-construction of such a plane to be challenging at the very least.

Because of their outstanding bush flying abilities, Cessna 180s and 185s command premium prices on the used market. While extremely well worn examples may fetch prices of $50,000 or less, these airplanes typically sell in the $50,000 to $150,000 price range, depending upon condition and avionics. Extremely well refurbished examples regularly sell at prices exceeding $150,000. Because of these prices, wrecked and project planes are quickly snapped up by price-weary Cessna aficionados. Cessna aircraft parts are still widely available for the 180/185 series airplanes.

Among the more significant changes 1966 of the Model 180H were:

The 180 and 185 are very similar in appearance, but the 185 has a larger dorsal fin attached to its vertical surface (although some 180s were produced with the larger fins and others have been modified to its specifications). Both aircraft are constructed of 2024-T3 Alcad aluminum using a semi-monocoque design with rivet fasteners. While the design was produced easily on an assembly line, the exact construction of the 180 and 185 would likely make kit-construction of such a plane to be challenging at the very least.

Because of their outstanding bush flying abilities, Cessna 180s and 185s command premium prices on the used market. While extremely well worn examples may fetch prices of $50,000 or less, these airplanes typically sell in the $50,000 to $150,000 price range, depending upon condition and avionics. Extremely well refurbished examples regularly sell at prices exceeding $150,000. Because of these prices, wrecked and project planes are quickly snapped up by price-weary Cessna aficionados. Cessna aircraft parts are still widely available for the 180/185 series airplanes.

Among the more significant changes 1966 of the Model 180H were:

- Improved door latches.

- Front seat legroom increased.

C-FTIH, seen here at Lac-A-La-Tortue airport (50km north of Trois Rivieres), is a year 2001 built Wag-Aero Sportsman 2+2.

The Wag-Aero Group is an American aircraft manufacturer, that was founded by Dick and Bobbie Wagner in the 1960s and is based in Lyons, Wisconsin. The company specializes in the design and manufacture of kit aircraft and aircraft parts for amateur construction.

The Wag-Aero CHUBy CUBy is a high-wing four-seat homebuilt cabin monoplane of tube-and-fabric construction, it is a modern representation of the Piper PA-14 taildragger with elements from other Piper family members. The plane is currently marketed as the Wag-Aero Sportsman 2+2.

The CHUBy CUBy was the third homebuilt replica of a Piper product from parts supplier Wag-Aero. The PA-14 line was a popular aircraft for Alaska floatplane operations, the CHUBy CUBy was put to market to allow new examples to be built.

The CHUBy CUBy closely resembles the Piper PA-14, but has several modifications. The recommended engine is the Lycoming O-320-E2D of 150 hp (112 kW) or Lycoming O-290 of 135 hp (101 kW) hung on a custom-designed swing-out engine mount. The CHUBy CUBy has swing-up doors on both sides of the cabin and two wing-mounted fuel tanks with a small header tank. The fuselage is welded from 4130 steel tubing rather than 1020 grade steel used in the original. The wings include spoilers to keep the aircraft on the ground and avoid floating.

Wag-Aero company president Dick Wagoner flew the CHUBy CUBy for the first time on May 8, 1982.

The Wag-Aero Group is an American aircraft manufacturer, that was founded by Dick and Bobbie Wagner in the 1960s and is based in Lyons, Wisconsin. The company specializes in the design and manufacture of kit aircraft and aircraft parts for amateur construction.

The Wag-Aero CHUBy CUBy is a high-wing four-seat homebuilt cabin monoplane of tube-and-fabric construction, it is a modern representation of the Piper PA-14 taildragger with elements from other Piper family members. The plane is currently marketed as the Wag-Aero Sportsman 2+2.

The CHUBy CUBy was the third homebuilt replica of a Piper product from parts supplier Wag-Aero. The PA-14 line was a popular aircraft for Alaska floatplane operations, the CHUBy CUBy was put to market to allow new examples to be built.

The CHUBy CUBy closely resembles the Piper PA-14, but has several modifications. The recommended engine is the Lycoming O-320-E2D of 150 hp (112 kW) or Lycoming O-290 of 135 hp (101 kW) hung on a custom-designed swing-out engine mount. The CHUBy CUBy has swing-up doors on both sides of the cabin and two wing-mounted fuel tanks with a small header tank. The fuselage is welded from 4130 steel tubing rather than 1020 grade steel used in the original. The wings include spoilers to keep the aircraft on the ground and avoid floating.

Wag-Aero company president Dick Wagoner flew the CHUBy CUBy for the first time on May 8, 1982.

C-GBUL is a 600 hp Redneck Turbine

|

C-GBUL rolled-off the Downsview production-line in 1953 and is seen here stored at Lac-a-la-Tortue (30km north of Trois Rivieres, Quebec). Re-engined with the seven cylinder 600 hp PZL engine, this Beaver is powered by 150 more horsepower than its original nine cylinder Pratt & Whitney R-985. This Beaver was manufactured for the U.S. Military and consequently became an L-20, designated 53-2797. After her military career she returned to Canada in 1976 and was registrated C-GFDJ. As such she served Silver Pine Air Service of Pine Falls, Manitoba and then with an operator in Peterborough. Exported to the U.S. in 1986, she returned once again to Canada in 1988. Club Cesar Inc. registrated her C-GBUL and operated this ship from Lac Cesar, Quebec, before Demolition Outaoua acquired her in 1994. Since 2003 Andre Durocher of Gatineau, Quebec is the owner of this PZL-Beaver.

Note; - This Beaver is already several years for sale. Her total flying time is +13,300 hours. Front view showing the larger engine cowling and the four-bladed PZL-driven propeller. The visible modifications on this Beaver are; - Wipaire 6100 straight floats with hatches, Wipaire skylight windows, extended cabin and large baggage door, wingtip tanks, Wipaire , Kenmore domed window to passenger doors, Kenmore rectangular fuselage windows, dual control yoke, Kenmore finlets and a ventral fin (as part of PZL installation). Conversion with 600-hp PZL Rotary engine with four-bladed prop was performed in 1985 at Airtech in Peterborough, Ontario. Ventral fin was fitted as part of PZL fitting. C-GBUL is for sale and this is the advertisement text:

DHC-2 MK-1 "THE BULL", TT 13,377.1, SMOH 509.9, SPOH 68.3, 1 VHF King KY 96A, 1 HF Codan 200, Straight Wipline 6100 new in 1996 with a big compartment in each float, "PRICE REDUCED", CANADIAN BEAVER, LOCATION: QUE Wheels: 35 inches tundra tires Kenmore seaplane finlets Ventral fin (part of PZL engine installation Wipaire Skylight windows. 2 Rosen sun visors. Kenmore domed windows in cabin doors. Kenmore enlarged (aft cabin) side windows. Enlarged baggage door. Extended baggage compartment. 56 inches deep. 145 MPH on wheels or floats @ 75% power and 40 GPH 1- Fuel flow is 10-15% lower than a regular Beaver. 18 GPH at 110-115 MPH. 2- Reliability is as good as or better than a regular Beaver. I have maintenance bills to prove this. 3- Parts are not difficult to find. I have all the parts for the next prop overhaul in 9 years. 4- Parts are less expensive than a regular Beaver. New propeller= $4 000. New engine= $10 000. 5- Labor is equal or less man hours than a regular Beaver. More space to work between 2 cylinders Engine(s) PZL-3S, 600 HP (piston), 0.0 SMOH , 1000 TBO, 7 cylinders |

Detail on port side fuselage, acknowledging 60th anniversary of the DHC-2 Beaver.

|

C-FTST is a 1969 built Cessna U206D Stationair 6 II of Forestair Inc.

The “U” designation indicated “utility” and this model was equipped with a pilot side door and large clamshell rear door serving the back two rows of seats, allowing easy loading of oversized cargo.

The “U” designation indicated “utility” and this model was equipped with a pilot side door and large clamshell rear door serving the back two rows of seats, allowing easy loading of oversized cargo.

C-FDLU is a Cessna 172M and she sits on her Baumann BF-2550 floats.

The 172M of 1973–76 gained a drooped wing leading edge for improved low-speed handling. This was marketed as the "camber-lift" wing.

The 1974 172M was also the first to introduce the optional 'II' package which offered higher standard equipment, including a second nav/comm radio, an ADF and transponder. The baggage compartment was increased in size, and nose-mounted dual landing lights were available as an option.

Total production of "M" models was 7306 over the four years it was manufactured.

The 172M of 1973–76 gained a drooped wing leading edge for improved low-speed handling. This was marketed as the "camber-lift" wing.

The 1974 172M was also the first to introduce the optional 'II' package which offered higher standard equipment, including a second nav/comm radio, an ADF and transponder. The baggage compartment was increased in size, and nose-mounted dual landing lights were available as an option.

Total production of "M" models was 7306 over the four years it was manufactured.

|

|

C-GDAU is a 1983 built Helio Courier 800 series. It is basicly a Helio-700 with a Lycoming IO-720-A1B engine.

The Helio Courier is a light C/STOL utility aircraft designed in 1949. Around 500 of these aircraft were manufactured in Pittsburg, Kansas from 1954 until 1974 by the Helio Aircraft Company. The design of the Helio features a large vertical tail surface and rudder for control at very low flight speeds. However, on conventional geared aircraft (taildraggers), the airplane tends to be sensitive to crosswinds, thus a crosswind gear option is available, allowing the main tires to caster left or right 20 degrees, increasing the crosswind component to 25 miles per hour (40 km/h). The Helio has its main gear placement far forward of the cabin, enabling hard braking on unprepared landing areas. The Super Courier was used by the US Air Force from 1958 onward, by the US Army Special Forces in the 1960s and 1970s and by Air America during the Vietnam War as the U-10. In U.S. Army and Air Force service, the U-10 Super Courier was used for liaison work, light cargo and supply drops, psychological warfare, forward air control (Air Force), insertion and extraction land and sea (Army) and reconnaissance. During the early 1980s, new owners (Helio Aircraft Ltd.) made an attempt to build new aircraft with direct-drive Lycoming engines, to replace troublesome and expensive geared engines. In a further effort to reduce weight, a new composite landing gear was featured. The new models also featured modest winglets. Two models were produced, the H-800 and H-700. A total of 18 aircraft were built. Helios remain very popular among bush pilots in Canada and Alaska and missionaries who fly into rough, relatively unprepared jungle airstrips because of its superior STOL abilities. Some operators use the Helio Couriers for aerial observation. |

C-FCFE is a Cessna 172M Skyhawk who sits on Baumann floats.

Baumann Floats closed her doors in 2011 due to the unfortunate economic conditions.

Baumann Floats closed her doors in 2011 due to the unfortunate economic conditions.

|

C-GUYT is a 1978 built Cessna R172K Hawk XP.

The FR172J Reims Rocket was produced by Reims Aviation in France from the late 1960s to the mid-1970s. It was powered by a Rolls-Royce built, fuel-injected, Continental IO-360-H(B) 210 hp (160 kW) engine with a constant-speed propeller. The Reims Rocket led to Cessna producing the R172K Hawk XP, a model available from 1977 to 1981 from both Wichita and Reims. This configuration featured a fuel-injected, Continental IO-360K (later IO-360KB) derated to 195 hp (145 kW) with a two-bladed, constant-speed propeller. The Hawk XP was capable of a 131-knot (243 km/h) cruise speed. The aircraft was well accepted for use on floats, however, as the standard 172 is not a strong floatplane, even with only two people on board, while the XP's extra power improves water takeoff performance dramatically. |

Propless C-GUXK is a also a Cessna R172K Hawk XP.

The Edo Aircraft Corporation The Edo Aircraft Corporation began operations on October 16, 1925. Although EDO's founder, Earl Dodge Osborn, had dreamed of building airplanes, his first successful product line was EDO floats. Because of a new innovative design, the use of aluminum rather than wood and the simple fact that good runways were hard to find in the 1920s, demand built quickly for the floats. With the outbreak of World War II, the company's focus shifted and EDO began to provide subassemblies for military aircraft. This shift in emphasis led to the company being renamed the EDO Corporation in November 1947.

The Edo Aircraft Corporation The Edo Aircraft Corporation began operations on October 16, 1925. Although EDO's founder, Earl Dodge Osborn, had dreamed of building airplanes, his first successful product line was EDO floats. Because of a new innovative design, the use of aluminum rather than wood and the simple fact that good runways were hard to find in the 1920s, demand built quickly for the floats. With the outbreak of World War II, the company's focus shifted and EDO began to provide subassemblies for military aircraft. This shift in emphasis led to the company being renamed the EDO Corporation in November 1947.

|

C-GWNR is a 1978 built Cessna 172K Hawk XP and powered by an 210 hp engine.

Floats or seaplane pontoons are a landing gear adaptation for an aircraft in which existing wheels are removed and replaced with hollow pontoons, supported by struts and spreaders, and attached to the fuselage with fittings that usually use the landing gear points. Your airplane must first have a “seaplane kit” in it. This usually consists of fuselage beef-ups, and a vee-brace in the cockpit. If the seaplane kit is already in the plane, installing floats for the first time will take from one to three days. After that, changeovers between wheels and floats can usually be done in a few hours. |

C-FYCA is a 1968 built Cessna 172K Skyhawk.

The 1969 172K had a redesigned tailfin cap and reshaped rear windows. Optional long-range 52 US gal (197 l) wing fuel tanks were offered. The rear windows were slightly enlarged by 16 square inches (103 cm2). The 1969 model sold for US$12,500 for the 172 and US$13,995 for the Skyhawk, with 1,170 made.

The 1970 model was still called the 172K, but sported fiberglass, downward-shaped, conical wing tips. Fully articulated seats were offered as well. Production in 1970 was 759 units.

The 1969 172K had a redesigned tailfin cap and reshaped rear windows. Optional long-range 52 US gal (197 l) wing fuel tanks were offered. The rear windows were slightly enlarged by 16 square inches (103 cm2). The 1969 model sold for US$12,500 for the 172 and US$13,995 for the Skyhawk, with 1,170 made.

The 1970 model was still called the 172K, but sported fiberglass, downward-shaped, conical wing tips. Fully articulated seats were offered as well. Production in 1970 was 759 units.

Built: 1968 - Conventional aircraft are planes with wonderful lines and always enchanted lovers in aviation.

C-FWTR is a 1968 built Cessna 182L Skylane in prestine condition! The Cessna 182 was introduced in 1956 as a tricycle gear variant of the 180. In 1957, the 182A variant was introduced along with the name Skylane. As production continued, later models were improved regularly with features such as a wider fuselage, swept tailfin with rear "omni-vision" window, enlarged baggage compartment, higher gross weights, landing gear changes, etc.

Four-seat 182N Skylane with fixed landing gear is powered by a 230 hp (172 kW) Continental O-470-R or O-470-S piston engine, gross weight 2,950 lb (1,338 kg) for take-off and 2,800 lb (1,270 kg) for landing. It was certified on 17 September 1969.

Four-seat 182N Skylane with fixed landing gear is powered by a 230 hp (172 kW) Continental O-470-R or O-470-S piston engine, gross weight 2,950 lb (1,338 kg) for take-off and 2,800 lb (1,270 kg) for landing. It was certified on 17 September 1969.

"It was time to hit the road again for the one hour drive to Aviation La Tuque which is located on Lac-à-Beauce".

Lac-a-Beauce

|

Lac-à-Beauce Water Aerodrome, is located on Lac-à-Beauce, Quebec, Canada and is open from May until the middle of November.

The seaplane lake-to-Beauce was officially inaugurated December 12, 1947 and is therefore one of the oldest in Eastern Canada. She has a bit in its own way, contributed to the development of Quebec by using the location seaplane forest fires, for medical evacuation in case of emergencies and the exploration for dam construction hydroelectric. She has also participated in tourism development in the Mauricie by transporting hunters and fishermen before the road communications will serve most of the sites reserved for such activities. However, the seaplane base has now turned to tourism in order to explore the area to visitors. |

Cessna 180 C-FDFF sits in front of Aviation La Tuque's dock on Lac-à-Beauce and is joined by another La Tuque Aviation Cessna.

It was in April 2012 that Remi Thibodeau became the new owner of the seaplane base. experienced bush pilot and entrepreneur at heart, he purchased the site in order to bring a fresh wind in the field. Thus Air St-Maurice changed its name to Aviation La Tuque. Since the clientele is increasing and the place continues to speak.

Although traffic is no longer what it was in the 90s, hundreds of tourists, fishermen and hunters continue to use public transport services by seaplane to get to the place of their choice from the 'seaplane du Lac-à-Beauce, which is now the only one in the region of La Tuque.

Although traffic is no longer what it was in the 90s, hundreds of tourists, fishermen and hunters continue to use public transport services by seaplane to get to the place of their choice from the 'seaplane du Lac-à-Beauce, which is now the only one in the region of La Tuque.

Cessna 185 Skywagon: The Pickup Truck of the Air

|

C-FDFF is a 1972 Cessna 185F Skywagon II of La Tuque.

Cessna introduced the 185 in 1961 as a more powerful version of the 180. Initally the 185 featured a 260 hp IO-470 Continental engine and in 1966 the engine was changed to a Continental IO-520 producing 285 hp. Modifications allow installation of engines up to 350 hp and, very rarely, a 185 will be seen with a small turbo-prop engine. This airplane will go just about anywhere you have the guts to take it and on those excursions will carry most of what you own. Skywagons haul the oil barrels, hunters, machinery parts, and caskets on work days; or the camping gear, cooler, and mountain bikes on days off. This aerial pick-up comfortably hauls nearly three quarters of a ton of stuff; in my airplane I can fill all four seats with 200-pounders, add a full tank of gas (88 gallons), and load more than 175 pounds of baggage. Airplanes able to do that comprise a very short list. |

"Skywagon II" had a factory fitted avionics package installed.

|

Love the tail art on this plane.

|

C-FVDG is a Cessna U206B Super Skywagon with a Robertson STOL kit of La Tuque Aviation. Faded marks of her former owner Aviation Mauricie are still visible.

The airplane, which started life as the U206, U standing for utility, never attracted a wide audience as a personal airplane. The faster 210 had a solid hold on that market. The 206, on the other hand, offered a little more room, a little more power and a better useful load compared with the 182. Cessna built almost 6,000 206s from 1964 up until the company halted its piston production in 1986, an impressive figure considering that during that time Cessna built tens of thousands of airplanes that competed for customers with the 206. Then and now, many 206s were operated by small air-taxi companies. |

Unforetunately the company's DHC-2 Beaver C-GAZJ was in maintenance at St. Mathias at the time of my visit.

"I had to hit the road as it was a long way to my next Port-of-Call, Air Saguenay, on shore of Lac Sébastien".