Ear Falls

|

Ear Falls

Ear Falls is a small township located in Northwestern Ontario, on the banks ofLac Seul and along Red Lake Road (Highway 105), 100 kilometers north ofVermilion Bay. The settlement was named after the eponymous falls. Many, many years ago, local Indians had named the place Ear Falls (Otahwaka Powitek) because the water had worn the rock ledge at the lip of the falls roughly in the shape of a human ear. The early French fur traders' name for the falls was Portage D'Oreille, or literally speaking, ‘carrying place of the ear’. More or less in the center of town is this Beech 18 'CF-EAR' on display. The registration is fake, just a reference to Ear Falls. It served with the Canadian Armed Forces and later several bush plane operators as CF-ZQG. It is at her present location since about the mid-1980's. Canadian Airways James Armstrong Richardson established WCA in March 1926 to serve the Red Lake gold rush. Operating out of Hudson and Winnipeg's Stevenson airfield. Reorganized in 1930 with the amalgamation of a number of carriers, while taking the name of one of the smaller companies it absorbed. Canadian Airways was an airline formed when Western Canada Airways bought out Commercial. It operated through the 1930s until it was purchased by Canadian Pacific Air Linesin 1941, carrying passengers on mail planes into smaller communities. Robert W. Arnold I received the following info of Robert W. Arnold: On a mighty cold day back in January 1984, two members from the Western Canada Aviation Museum in Winnipeg,Tony Morien, Chief of Restoration, and myself had the challenging task of moving by road Beech 18-3TM, CA-125 RCAF 5184 from Red Lake to Ear Falls Ontario. The aircraft was civilian registered as CF-ZQG. I cannot remember why we went at such a bitterly cold time of year. I know they assembled it and it sat on the ground for a while in Ear Falls before it went up on the pole. |

|

|

Kay Air Service & Outposts Kay Air float-plane base is located 5 miles south of the community of Ear Falls. Peter and Karen Kay advertise their Fly-In Outposts as follows; - Arrive early at KayAir’s Home Base located on beautiful Lac Seul five miles south of Ear Falls. We will weight and load your fishing gear, luggage and bait on the plane. You will then take off from Lac Seul, head north and land on your desired lake. You are now ready to fish for the next 3-7 Days”. On the dock I met Peter Kay, owner of the company, who gave me permission to take photographs. Where his Beech 18 and a Cessna 180 floatplane were moored on the dock. C-FTBH is a former C-45F Expeditor. She served the US military and was later modified to Beech 3T. This aircraft has a set of Hartzell three blade propellers instead of the typical two blade Hamilton Standard props. C-FTBH was registered to KayAir Service in June, 1995. The other aircraft on the |

|

Whitewing Resort

Jim and Wilma Fullerton founded Whitewing Resort in the early 1960's when the Army Corp of Engineers was still filling the artificial Lac Seul. They ran the resort and raised two boys. After many years, they sold the property and in the following years the resort changed hands several times. The Daily Family is running White Resort since 2001. The Whitewings Piper PA-18 Super Cub is a two-seat, single-engine monoplane. Introduced in 1949 by Piper Aircraft, it was developed from the Piper PA-11and traces its lineage back through the J-3, to the Taylor E-2 Cub of the 1930s. In close to 40 years of production, over 9,000 were built. Super Cubs are commonly found in roles such as bush flying, banner and glider towing. Whitewing Resort Piper 18 C-FJVK was manufactured in 1951. |

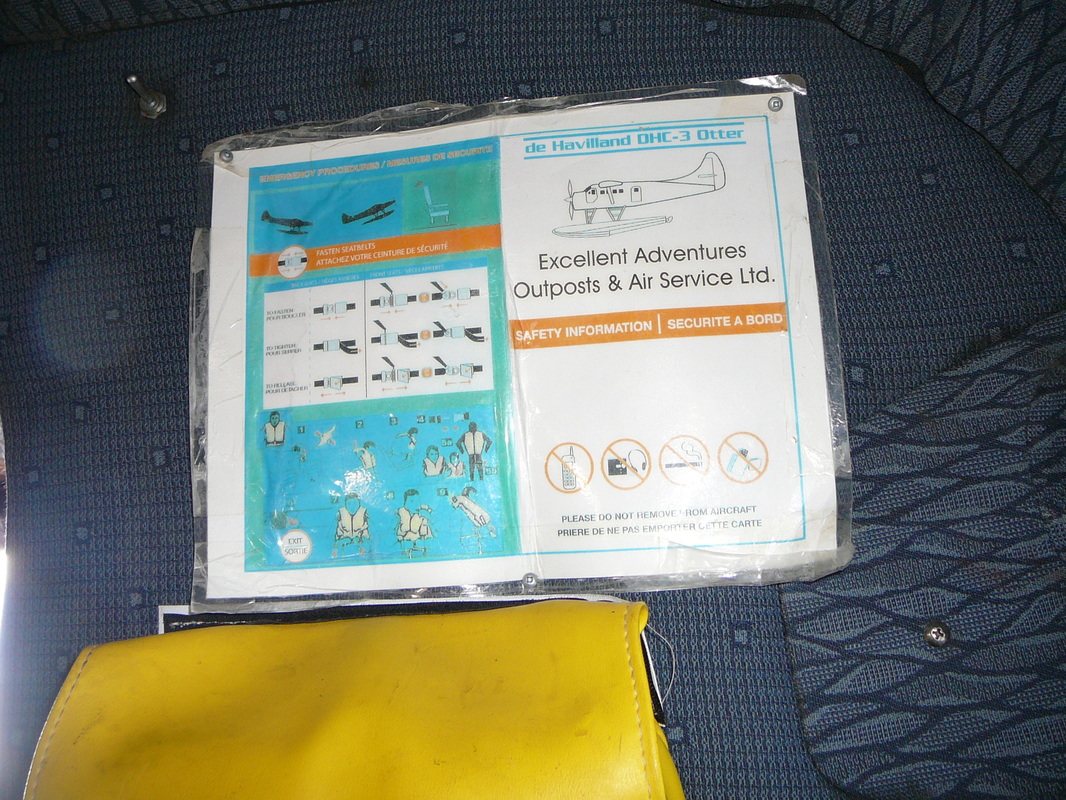

Here at Lac Seul in June 2013. This basic Otter was built by De Havilland Canada 53 years ago. It seems that this Otter has flown some time in Australia. It returned to Canada in 2006 and was advertised for sale in 2007 for CAD 735.000. C-FBEO was acquired by Excellent Adventures Outposts & Air Service in May 2007 and is good and tight machine

The unusually wide cabin doors, combined with the generous cabin dimensions and folding passenger seats provide rapid flexibility in mixed passenger/cargo ratios. The left double freight doors open to 118 cm and the right one to 76.2 cm . These and many other features are essential to quick turn-around-time

|

|

Excellent Adventures

Excellent Adventures float-plane base is located 3 miles south of the community of Ear Falls, Ontario. The company offers remote outpost fly in fishing vacations to virgin wilderness onboard their broad shouldered piston Otter. C-FBEO DHC-3 Excellent Adventures C-FLBL Aeronca 7B private Excellent adventure’s base at Perrault Falls is just south of Ear Falls on Highway 105. The natural attractions of this wild, magnificent part of Canada is legendary and it is worth lingering in the Lac Seul region to discover the stupendous scenery, moose, bald eagles, and – if you’re lucky – black bears foraging on Red Lake road. We wandered to the office to find out when the company’s piston Otter was due to return. One of the first things that caught our eyes was a large mural depicting the history of Excellent Adventures and the aircraft that it had operated over the years. |

|

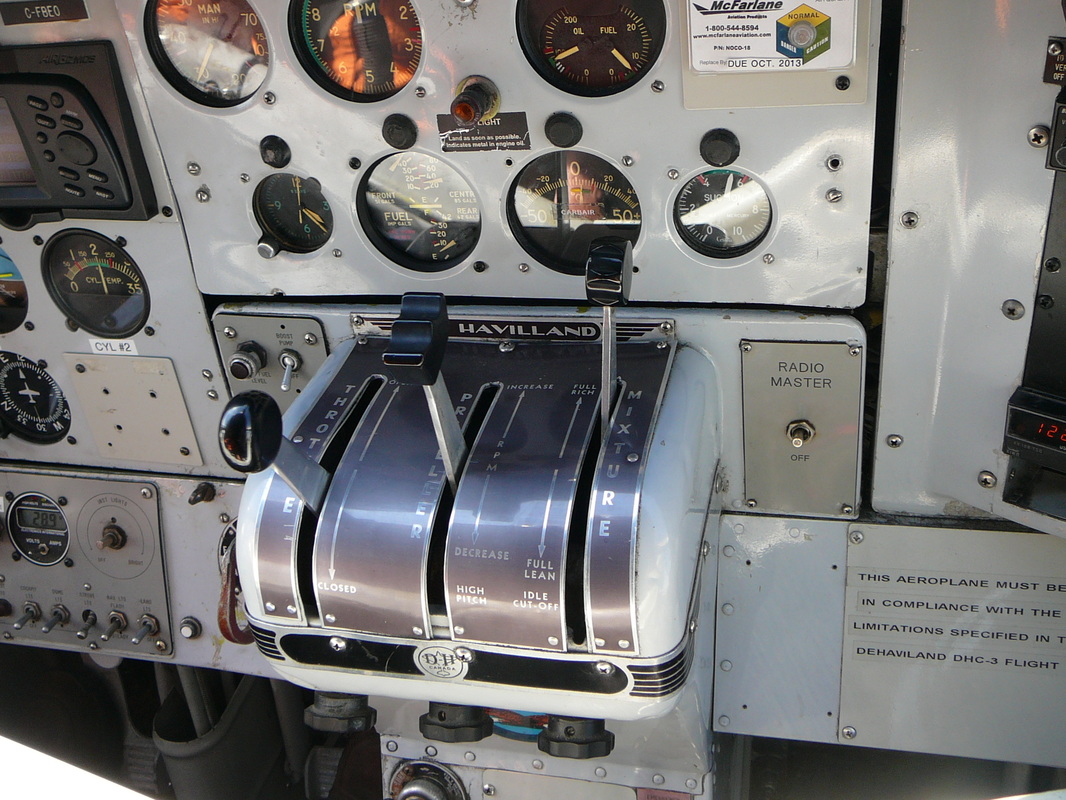

Get acquainted The DHC-3 Otter airplane is an all-metal, high wing monoplane powered by a single Pratt and Whitney Wasp engine driving a Hamilton Standard constant speed propeller. The aircraft has been designed to carry a pilot and from six to eleven passengers. Through partitions the aircraft is divided into a cockpit, a cabin and a baggage compartment. The Otter has proved to be a very versatile aircraft. As a seaplane, it has enabled many lake-studded countries to open up new territory. The ability to haul full loads out of small lakes under conditions of no wind, was developed form experience gained from its predecessor, the Beaver. The Otter seaplane, at full gross weight of 7,967 lb. (3,614 kg.) takes off glassy water in a distance of 1,050 ft. (320 meter). The Otter lands in 740 ft. (226 meter), operating out of lakes 1/3 mile (531 meter) in length. Otter seaplanes are operating in both salt and fresh water areas, consequently the airframe is treated for corrosion prevention, protecting all the metal surfaces both internally and externally. The high-wing construction of the Otter offers the bush operator a great advantage in being able to move alongside docks or swing-in over shorelines, particularly during low water level. The shallow 23 inch (58 cm) float draught allows the aircraft to be taxied in close to the shore, facilitating the handling of cargo and/or passengers. The General over-all dimensions of the airplane are; length 41 feet, 10 inches, wing spans 58 feet and height 12feet, 6 inches. The maximum gross weight of the aircraft is 7967 pound for a seaplane. The airplane is powered by a Pratt & Whitney Wasp R-1340, geared nine cylinders, air-cooled, radial, supercharged engine rated at 600 BHP. The supercharger is of the direct-connected, engine driven centrifugal type and is not under control of the pilot. The two exhaust augmentor tubes on both sides of the fuselage, just below the cockpit door, are a special design feature of the aircraft. In these four exhaust augmentor tubes, the exhaust gases produce suction strong enough to pull cooling air around the engine and from behind the engine accessories compartment while at the same time providing a measurable amount of thrust in cruising flight. The engine is thus effectively cooled during steep climbs when the forward air speed is low and engine output near its maximum. Engine controls. The throttle control lever at the left of the quadrant at the top of the pedestal slides in a gate marked CLOSED and OPEN. The lever is connected by a flexible cable and conduct control to the carburetor throttle valve. A friction control below the throttle lever prevents throttle creep when rotated clockwise. The fuel air mixture ratio is manually determined through the mixture control lever at the right of the quadrant. Reading from the rear to the front, positions marked on the quadrant gate are: IDLE CUT-OFF, FULL LEAN and FULL RICH. A friction control knob below the control lever prevents the control from creeping and permits to set and permits to set any intermediate position, when tightened clockwise. Conventional engine instrument are mounted on a panel above the engine controls quadrant. They consist of; a tachometer, a manifold pressure gage, a cylinder head temperature gage, a carburetor mixture temperature gage, an oil pressure gage, an oil temperature gage and a fuel pressure gage. The tachometer indicator is operated by an electrical generator driven by the engine. A triple indicator fuel contents gage and a clock are also located on the engine instrument panel. The engine ignition switch is located on the starter panel below the pilot’s flight instrument panel. The switch is marked OFF, R, L and BOTH. The carburetor hot air control lever is located on the left side of the base of the pedestal and is mechanically linked to a barrel valve in the carburetor air intake. When the lever is in the COLD position, cold ram air enters the carburetor through the shielded air intake. As the lever is moved downwards towards the HOT position, the barrel valve progressively closes the ram air intake while it opens another duct. This second carburetor air duct allows heated air from the inside of a heat exchanger muff which surrounds a section of the engine exhaust collector, to mix with the cold ram air before delivery to the carburetor. Thus, intermediate positions of the lever between fully up and fully down give varying carburetor air intake temperatures. With the carburetor air control lever in the HOT position, the ram air intake is fully closed and hot air from the heat exchanger muff only is ducted to the carburetor. The resulting mixture temperature is indicated on the carburetor mixture temperature gage. The hand-operated cylinder primer pump injects fuel into cylinders numbers 1, 2 , 3, 8 and 9. It is located on the left side of the pedestal, below the engine controls quadrant. To unlock the primer, the pump handle is to be pushed in and rotated anti-clockwise. After use the primer pump handle must be relocked by pushing in and rotating clockwise in order to prevent engine flooding and a fire risk when the booster pump is switched on. The engine is started by an electrical, direct-cranking starter. The starter switch for the electrical direct-cranking starter motor and the two starter switches required for the electrical inertia starter are located on the starter panel below the flight instrument panel. The switch or switches are spring-loaded to the OFF position. A boost coil switch is located on the starter panel. This switch is also spring-loaded to the OFF position. The engine drives either a Hamilton Standard, three bladed, constant speed, counterweight type propeller or a Hamilton Standard, three bladed, hydromatic, non-feathering propeller. The engine rpm are determined by the setting of the propeller control lever located on the quadrant on top of the pedestal. The control lever is connected to the propeller governor by a flexible cable and slides in a gate marked HIGH PITCH, DECREASE RPM and INCREASE RPM. The propeller governor automatically maintains any selected rpm within the operating range of the propeller, regardless of variation in air loads or flight attitudes. A friction control below the propeller control lever prevents the lever from creeping when rotated clockwise. The governor maintains the propeller blades within the constant speed range by supplying oil at engine pressure to the outboard end of the propeller actuating piston which, together with the centrifugal twisting moment acting on the blades, tends to move the blades towards low pitch. To balance the effect of both these forces, engine oil is boosted in pressure by the engine driven propeller governor and is passed to the inboard end of the propeller actuating piston to the blades towards high pitch. The propeller pitch can be changed by reselection of the propeller control lever which varies the load on the governor fly-weight and allows the governor pilot valve to take up a new position to maintain the propeller at the new selected constant speed setting. The oil tank, which is of 9 Imp. gal. (40,5 liters) capacity is located under the cockpit floor. Servicing of the oil tank is done through a filler neck on the left side of the fuselage. The oil cooler with an integral surge relief valve and a thermostatic by-pass valve is located behind the firewall and has its own air-flow system. Fuel is contained in three flexible bag-type tanks beneath the forward portion of the cabin floor. The tanks are buttoned with fasteners to the underside of the floor, to stringers and the skin of the fuselage. The tank capacity is as follows; front tank 51 Imp. Gal (233 liters), Center 85 Imp. Gal (389 liters) and the rear tank 42 Imp. Gal. (192 liters). The center tank consists of two interconnected cells. Each of the three tanks is used separately, the fuel flow to the engine being controlled by the fuel selector valve. An electrically-operated booster pump ensures that an adequate fuel flow is maintained in the event of failure of the engine driven pump. The fuel selector handle, located below the bottom right corner of the pilots instrument panel, can be positioned to FRONT TANK, CENTRE, REAR TANK or OFF. When the engine is not operating, the selector handle must be selected to OFF to prevent drainage of the fuel supply line into the tank. The fuel booster pump switch is located on a panel to the left of the engine controls quadrant. A combined fuel pressure, oil pressure and oil temperature gage is located on the engine instrument panel above the engine controls quadrant. The triple indicator fuel contents gage, graduated either in Imperial or U.s. gallons, will indicate only when the FUEL CONTENTS circuit-breaker is set. This switch is located on the junction box circuit-breaker panel, behind the copilot’s seat. A warning light gives an indication of low fuel level in the tank from which the engine is operating. The light becomes illuminated when fuel for approximately 15 minutes of cruising remains in the tank. The shut-off control handle stops the supply of both fuel and oil to the engine in case of emergency. It is located on the right side of the pedestal, below the engine controls quadrant. Electrical energy is supplied by a direct current 50 amp. 28-30 volt generator in conjunction with a 24 volt 24 amp-hr. storage battery. Installations of generators of 80 to 100 amp. And batteries up to 35 amp-hr. have been made. All circuits of the electrical system are protected by manual reset-type circuit-breakers on the junction box panel behind the co-pilot’s seat or on the electrical switch panel on the co-pilot’s sub-panel. The battery is inside the baggage compartment on a shelf in the rear right-hand corner. The following equipment and controls are supplied by the electrical system; engine starter, booster coil, fuel booster pump, pitot head heater, engine fire ext. system, instrument and warning lights, interior lights, navigation lights, landing lights, heater installation, radio and communication equipment. For starting the engine or for electrical ground checks, an external power source may be connected to an external power receptacle fitted to the right side of the fuselage, aft of the cabin door. Access is gained through a spring-loaded hinge panel. When external power is connected, the aircraft battery is isolated if the battery master switch is in the OFF position. The battery master switch on the starter panel, is of the double-pole, single-throw type and serves also as the generator field switch. A volt-ammeter is on the electrical switch panel. The instrument constantly shows the number amps. being delivered to the system and the battery. When pressing the button on the left side of the instrument, the generator output voltage is indicated. All control surfaces are mass-balanced and are conventionally operated by a control column and rudder pedals. The handwheel portion of the control column may be ‘thrown-over’ for use by a co-pilot, in conjunction with the installation of rudder pedals on the right side of the cockpit. The wing flaps are of the full-span, double-slotted type. The outboard trailing edge portions of the flaps are operated independently as ailerons. The incidence of the tailplane may be adjusted in flight by may be adjusted in flight by rotating the TAILPANE TRIM handwheel at the right side of the pilot’s seat. The handwheel operates in the natural sense and its pointer moves over a labe marked NOSE DOWN, TAKE OFF SETTING and NOSE UP. The area marked TAKE OFF SETTING is edged in green. The neutral position of the tail-plane trim is marked 0 with further markings to 2 in the NOSE DOWN direction and to 5 in the NOSE UP direction. The rudder trim tab is actuated by a handwheel in the cockpit roof. The handwheel assembly incorporates a position indicator which movers over a scale marked L and R indicating the direction an amount of trim applied. The aileron trim which is adjusted by means of a handwheel on the control column varies the tension left or right of the aileron control cable in flight. Fixed trim tabs on each aileron are provided for adjustment on the ground by qualified servicing personnel. The pilot’s rudder pedals may be adjusted for leg reach. By pulling the adjusting knob, the pedals can be moved to the desired position and secured in that position by releasing the adjusting knob. The wing flaps are operated hydraulically by a flap actuating jack assembly, located in the fuselage roof between the front and rear wing attachment lugs. Hydraulic fluid, contained in a separate reservoir located aft of the firewall on the left-hand side, is pumped into the flap actuating jack assembly by means of a handpump located beneath the pilot’s seat. Wing flaps are selected UP or DOWN with a selector lever and after they are pumped to the desired position with the handpump, they are automatically locked by a hydraulic ratchet valve which is part of the flap actuating jack assembly. The wing flaps are mechanically connected to the trim tab on the left elevator so that actuation of the wing flaps automatically deflects the trim tab to maintain the longitudinal trim. The handpump lever is in line with the right-hand side of the pilot’s seat and is operated in a fore-and-aft movement. The wing flaps selector lever is mounted on the tailplane trim pedestal, to the right of the pilot’s seat. CRUISE, LAND, or intermediate positions of the wing flaps are obtained by moving the wing flaps selector lever to up or down position and then pumping the flaps to the desired position, as shown on the wing flaps position indicator. Note when the wing flaps have been pumped to the desired position, the wing flaps selector lever should immediately be moved to its neutral position, to provide an addition lock on flap motion. The wing flaps position indicator is located on the vertical frame member of the windshield and is marked UP, CRUISE, CLIMB, TAKE-OFF, LAND and DOWN. A shock-mounted flight instrument panel is provided for the pilot and incorporates the following flight instruments; Airspeed Indicator, Altimeter, Artificial Horizon, Directional Gyro, Rate-of-Climb Indicator, Turn-and-Bank Indicator, Magnetic Compass, Radio Compass and space provision for another flight or Navigation Instruments like a GPS. Pitot-Static operated instruments comprise: Airspeed Indicator, Altimeter and Rate-of-Climb Indicator. The engine driven vacuum pump provides suction to operate; Directional Gyro, Artificial Horizon and Turn-and-Bank Indicator. The artificial horizon is operated by the vacuum system and gives bank, dive and climb indications. A knob at the bottom of the instrument dial adjusts the vertical position of the miniature airplane for fore-and-aft attitudes of the airplane. A caging knob permits to lock the instrument in the upright position and provides a rapid means for resetting if the operating limits of the instruments are exceeded. The operating limits are set to permit 60 degrees climbs and glides and 100 degrees right of left banks before the limit stops are reached. The suction gage is located on the engine instruments panel. The gage is calibrated from zero to 10 in. Hg. The outside air temperature gage is located in the cockpit roof. It is of the direct-reading bulb type. Its dial is graduated in degrees Fahrenheit and Centigrade. The engine fire extinguisher system is controlled from the fire extinguisher panel below the flight instrument panel. The system in corporate a fire extinguisher bottle, flame switch and a length of fuse wire located in the engine compartment. In the event of fire, a red warning light on the extinguisher panel is illuminated and the EXTINGUISHER SWITCH must be switched on to discharge the bottle after the engine is shut down. Both the warning light and the extinguisher circuits are protected by push-to-reset button type circuit-breakers on the fire extinguisher panel. A hand-operated fire extinguisher in a quick release clip is attached to a bracket to the left and rear of the pilot’s seat. A first-aid kit is stowed in a bag located on the right-hand cabin side between the passenger door and the rear cabin bulkhead, aft and above the door lock. A second first aid kit may be installed behind the pilot’s seat in the cockpit. A 27-inch diameter hatch has been provided in the rear cabin floor just aft of the rear cabin bulkhead normally closed by lids screwed to the floor and out skin of the fuselage. A trap door may be installed. The cabin side seats may be folded flat against the wall, flush with the base of the heater duct. The rear seat hinges up against the rear cabin bulkhead. All seats have padded backs, buoyant seat cushions and lap safety belts. Fourteen cargo tie-down rings, eight of which are permanently installed are supplied with each aircraft. Eighteen receptacles to receive the six removable cargo tie-down rings permit to secure any type of cargo. An additional number of receptacles may be provided. Relief tube may be installed in the cockpit on the right-hand side of the pedestal and in the cabin. The relief tube for the cabin is located in the baggage compartment. “End of the manual” |

|

The cabin is 1.5 meter by 1.5 meter wide and has an overall length of 5 meter . This provides a total volume of 9,8 cubic meters and includes the rear stowage compartment which is separated by a removable bulkhead. The cabin interior is fitted to accommodate nine passengers, eight passenger seats in the cabin and one beside the pilot. The seats can be folded against the cabin wall to enable all of the cabin space to be utilized for cargo. If desired, they can also be quickly removed and their weight deducted to obtain additional freight payload. With the seats folded, the Otter becomes literally a ‘flying truck’, capable of handling heavy loads of bulk cargo

|

|

Bruce is our pilot Our pilot introduced himself as Bruce and asked for a volunteer to sit in the co-pilot’s seat. My offer was made in an instant and was luckily accepted. I took my seat in the cabin, strapped myself in. Bruce checked that all the passengers were strapped in securely and then gave the safety briefing. He signaled to the ground crew to release the mooring lines and then started the big radial engine, which coughed and then burst into life. When power was increased, the aircraft vibrated, rattled and off we went! |

While flying high over the marsh, boggy area with millions of trees, our massive Pratt & Whitney R-1340 is burning 40 Imp. gallons per hour.

All to soon are Otter swooped low over the threes and crossed the shore of Lac Seul, alighting on the glistering water with the characteristic whoosh as the floats contacted the surface

|

Showalter’s

About 40 minutes drive north of Ear Falls, located on the right-hand side of the road you will find the small and quaint Showalter base. It’s very a photogenic place, located at Trout Lake River, which is situated between Bruce Lake and Pakwash Lake. For over 50 years, members of the Showalter family have been providing fly-in fishing adventures. Ralph, Manly and Edwin Showalter eventually became some of the most experienced bush pilots ever to fly the northern regions of Canada.In 1987, Edwin, his wife Louise and son Eddie Showalter moved to Ear Falls, Ontario and began their operation "Showalter's Fly-In Service" with a fleet of two Beechcraft 18's, one Beaver and a Cessna 180. In 2008, after a long and legendary 50 year aviation career, Edwin retired. He and Louise sold the company operations to their son Eddie. In the air since the age of 15, Eddie still flies his red and white Cessna 180 for routine camp checks and has now accumulated more than 20,000 flight hours and became an expert on northern Ontario fishing and hunting. The family now operates twelve of the top remote fly-in outpost camps in Northwest Ontario. Under Eddie's management, his family's reputation for high levels of customer service and safety continues to bring guests back year after year. Showalter’s Fly-inn is the proud owner of two Beechcraft 18’s. As already mentioned; - “There are now few commercial operators left anywhere flying the Beech 18 and certainly only a handful still operating the “Twin Beech” on floats. Trout Lake river it one of the few places left where one can still enjoy the distinctive sight and sounds of the venerable Beech 18 floatplanes in regular operation. Both Beechcraft are often used on Showalter’s trunk route to Carroll and Irvine Lake on the Manitoba–Ontario border in Woodland Caribou Provincial Park. C-FZYE C-FZYE was delivered in 1952 to the Fuerza Aérea de Chile. Its civilian career started 1969 in the US but she was soon exported back to Canada in 1971 and registered as CF-ZYF. Fate struck a blow when it crashed on July 24, 1992 at Unegam Lake, Ontario. The Beaver was found inverted in water after an engine failure. She was totally rebuilt and went to Wilderness Air of Vermilion Bay, in 1996. Since April 2007 ‘Yankee-Echo’ has been registered to Showalter's Fly-in Service Ltd. but retained the sparkling colors of Wilderness Air. C-FAIH In the late afternoon Showalter’s Cessna 180 C-FAIH arrived at the dock. Brad Bloise appeared to be the driver. We had met Brad some days before at Minaki, while performing crew training with a youngster at Pistol Lake. When we inquired about their Beechcraft, C-FZNG, Brad said it was at the Minaki airstrip after a maintenance check and should be pick-up later that afternoon. He asked us if we would like to fly up to Minaki in the Skywagon and return in the Beech 18. We immediately consented. First we had to pick-up Peter Kay of KayAir, who would fly back the Skywagon. With Brad behind the controls, C-FAIH thundered across the water on its take off run and in seconds the venerable Skywagon was airborne. Brad is a very kind person and a very experienced bush plane driver with a total of 19,000+ flying hours in all kind of bush planes. Presently Brad is working for Kenn Borek as a pilot on their Basler DC-3T’s and is often working in Antarctica flying German scientist to and from their camps. Visibility was excellent and we could see fishing boats on the dark green lake, with island capped with pine trees. It’s only a short hop from Showalter’s to Peter Kay’s floatplane base. After Peter had clambered into the Skywagon we set course to Minaki. Preflight Inspection of the Cessna 180H Visually check airplane for general condition during walk-around inspection. In cold weather, remove even small accumulations of frost, ice or snow from wing, tail and control surfaces. Also, make sure that control surfaces contain no internal accumulations of ice or debris. Prior to flight, check that pitot heater (if installed) is warm to touch with 30 seconds with battery and pitot heat switches on. If a night flight as planned, check operation of all lights and make sure a flashlight is available. Cabin Pilot’s Operating Handbook – Available in the airplane. Control Wheel Lock – REMOVE. Ignition Switch – OFF. Avionics Power Switch – OFF. Master Switch – ON. Fuel Quantity Indicators – CHECK QUANTITY. Master Switch – OFF. Static Pressure Alternate Source Valve – OFF. Fuel Selector Valve – BOTH ON. Baggage Door – CHECK securely locked. Empennage Rudder Gust Lock – REMOVE. Floats – Drained and Check for damage. Control Surface – CHECK freedom of movement and security. Right Wing Trailing Edge Aileron – CHECK freedom of movement and security. Right Wing Wing Tie-Down – DISCONNECT. Fuel Tank Vent Opening – CHECK for stoppage. Before first flight of the day and after each refueling, use sampler cur and drain small quantity of fuel from fuel tank sump quick-drain valve and fuel line quick-drain valve (located on bottom of fuselage below the cabin door) to check for water, sediment and proper fuel grade. Fuel Quantity – CHECK VISUALLY for desired level. Fuel Filler Cap – SECURE and vent unobstructed. NOSE Static Source Openings (both sides of fuselage) – CHECK for stoppage. Propeller and Spinner – CHECK for nicks, security and oil leaks. Carburetor Air Filter – CHEK for restrictions by dust or other foreign matter. Engine Oil Level – CHECK. Do not operate with less than nine quarts. Fill to twelve quarts for extended flight. LEFT WING Fuel Quantity – CHECK VISUALLY for desired level. Fuel Filler Cap – SECURE and vent unobstructed. LEFT WING Leading Edge Pitot Tube Cover – REMOVE and check opening for stoppage. Stall Warning Opening – CHECK for stoppage. To check the system, place a clean handkerchief over the vent opening and apply suction; a sound from the warning horn will confirm system operation. Fuel Tank Vent Opening – CHECK for stoppage. Wing Tie-Down – DISCONNECT. LEFT WING Trailing Edge Aileron – CHECK freedom of movement and security. STARTING ENGINE Mixture – RICH. Propeller – HIGH RPM. Carburetor Heat – COLD. Throttle – OPEN ½ inch. Prime – AS REQUIRED. Master Switch – ON. Propeller Area – CLEAR. Ignition Switch – START (release when engine starts). Oil Pressure – CHECK. TAKE-OFF Wing Flaps – 0° or 20°. Cowl Flaps – OPEN. Carburetor Heat – COLD. Power – FULL THROTTLE and 2400 RPM Elevator Control – MODERATE TAIL LOW. Climb Speed – 85 KIAS. Wing Flaps – UP after obstacles are cleared. |

|

|

Brad, a happy Twin Beech driver! In the distance the sunlight broke through the overcast and shone like a golden shaft on the dark waters below portraying some magnificent scenery in this remote area of Ontario. C-FZNG Showalter’s Beech 18 C-FZNG awaiting collection at Minaki Airport, prior to the flight to the Showalter’s base on June, 08. The Beech has the two-piece windshield, what appears to be a Hamilton nose cap, Hamilton Standard Hydromatic props and a Beechcraft cargo door. C-FZNG was constructed in 1952 as Beechcraft D-18S for the RCAF and was converted in the 1960's for civil use by removing navigational training equipment and installing more seats. ‘November-Gulf’ did operate for operators like; Silver Pine Air Services and Red Lake Airways, before she was bought by Eddie Showalter's in 1988. P&W 985 radial engines While the Beech 18 was never intended to be used for the "budget-conscious" pilot, because the two P&W 985 radial engines will consume close to a barrel of fuel per hour, it is capable of being a perfect, no-frills, bush plane. Twin Beech aircraft will cruise at speeds close to 200mph on wheels and 145mph on floats and can haul 8 people.' Video Ferry flight of ‘November-Gulf’ We said goodbye to Peter, who flew C-FAIH, back to the Showalter’s base. After we prepared C-FZNG for her ferry flight, I climbed up into the fuselage, walked through the spartan cabin and as I entered the cockpit I strapped myself in and I admiredd the flight deck instrumentation with classic round dials and gauges and noticed the latest technology Global Positioning System (GPS) equipment, as well a standard radio fit. Once Brad had entered the cockpit, he gave us the safety briefing, explained that emergency equipment and rations were at the rear of the cabin. Then he signaled to the staff to push the Beech away from the dock. Seconds later the starboard Pratt & Whitney R-985 radial busted into life in characteristic fashion and the Beech came alive and began to vibrate. Then the port engine was fired up and as the noise level increased the headset became most welcome. Brad turned toward the middle of Pistol Lake and did a full and thorough power check prior to departure once the oil had warmed sufficiently, meanwhile I had to take care not to touch the rudder pedals or the control yoke. Take-off checks were started

Take-off checks were started once the roof hatch had been closed and after checking for any boats or flotsam, Brad applied take off power. Both Pratt & Whitney R-985 engines roared enthusiastically as the Beech accelerated across the water, rose on the step and was soon airborne. During a climbing turn, I could see the River Air floatplane base below and when gazing to the horizon I realized just how many lakes there are in the area. As the airspeed increased the Beech climbed to almost 5,000 feet just beneath the cloud layer and the throttle went back to 29 inches Hg. manifold pressure and the propeller gave 2000 rpm. These settings gave us a cruising speed of around 120 knots. For this short flight at low level, at an outside temperature of 62 degrees Fahrenheit the mixture levers remained full rich and carburetor mixture temperature was 10 degrees Celsius. Oil temperature was 80 degrees Celsius with a pressure of 80 psi. The R-985’s cylinder heat remained within limits at 400 degrees Fahrenheit. 100LL Avgas fuel burn was a healthy 45 US gallons per hour at the cost of CAD 1.78 per liter. A gentle splash as the floats brushed the water Closer to Ear Falls, the small town of Red Lake could be seen and after twenty minutes taking in some of the Ontario’s most beautiful scenery, Brad began the descent towards Bruce Lake. Our flight path took us over Showalter’s floatplane base where flaps were lowered for landing. Brad explained his technique in watching the waves to assess wind and water conditions for the landing. Shortly after passing the shoreline of the lake, there was a gentle splash as the floats brushed the water and the Beech decelerated as she settled onto the water. Once at taxiing speed, Brad negotiated the narrow channel between Bruce Lake and Pakwash Lake which took us towards the company dock. Brad opened the roof hatch and then disappeared out of the cockpit, soon to reappear on the dock with the mooring rope in hand and securing the Beech. We thanked Brad

We thanked Brad for the interesting trip and his expert commentary on the area. It was an amazing experience at a truly magical and picturesque location. We then retired to a shabby motel down the road to Ear Falls where we relaxed over dinner and a few beers, reflecting on what had been a truly memorable day. |

|

|

Showalter’s

Next day we were back at the Showalter’s base to enjoy a day long bush plane action first handed. Morning has come. "Action time" is not far away After a short time fishermen were walking down the jetty to board individual aircraft and the first departure rotation of lodge change over-flights was underway. Showalter’s, as many other operators, has his own cabins on lakes out in the bush C-FXUO was manufactured in 1952 and was handed over to the RCAF. After her military duties were over the Beech was made surplus in 1966-67. ‘Uniform-Oscar’ went to the U.S. for some years but came back to Canada in 1972. Canadian operators included Nunasi-Central Airlines, Green Airways, Pickle Lake Air Services and Kelner Airways, Beaver Air, Ignace Airways and Showalter's Flying Service since 1990. Showalter's both D-18S floatplanes, have the Bristol mod with 56-7850 floats and cockpit hatch on the top. C-FXUO has a two-piece windshield, Hamilton Standard 22D30 props and a Beechcraft cargo door. Float-equipped Beech 18s are notoriously quite a handful for any pilot in gusty conditions or when flying on a single engine and hence, the additional large dorsal fin on the twin-tailed Beech is very functional to assist with directional stability. |

|

|

Flight to Carroll & Irvin Lake

A party of sport fishermen was unloading their vehicles of their fishing tackle, equipment and we assisted Brad with loading the baggage, groceries, household goods and mail. Keep in mind; you have to be strong and fit to handle a Twin Beech! Both Showalter’s Beech 18’s were chartered by a group of fisherman who would camp at Showalter’s lodge at respectively Carroll and Irvin Lake. Both are around 30 minutes flying time form the company’s base. There were four other passengers, making a grand total of seven. Once the passenger door was closed again, Brad pushed the floatplane away from the dock and then arrived in the cockpit through the open roof hatch. He courteously welcomed everyone on board and gave a brief safety talk. He then gave me a spare headset so that I could listen into the R/T and talk to him on the intercom. When the floatplane started its take-off run When the floatplane started its take-off run, the roar of the Pratt & Whitney R-985 Wasp radial engine reverberated off the hills surrounding the dock. The Beech accelerated on the foaming water, rose on the ‘step’ and with gentle rearward movement on the control column, ‘Uniform –Oscar’ became airborne. Visibility was good and five minutes into the flight, the town of Kenora came into view. As we flew overhead, I could see several floatplanes maneuvering on the water below. There was some chatter on the ATC frequency as we passed Red Lake and thereafter unfolded a panorama of picturesque lakes and boreal forest. As we turned towards Carroll Lake, I could see the Eddie Showalter’s other Beech in the far distance as we were following the same route. Before landing on the lake, Brad did an aerial surveillance of the area checking for obstructions such as floating logs or rocks close to the surface of the water. Wind direction must also be taken into account. Different techniques are required for on-shore winds than would be sued for off-shore winds. Flaps were lowered and the approach to Carroll Lake began. The floats gently brushed the water The floats gently brushed the water with a ‘splash’ and the aircraft decelerated. Brad taxied the Twin Beech towards the dock and shut down both engines to let the floatplane gently drift in the water. This is the moment where the judgment of the pilot is essential, if the dock is approached too fast there is the danger of a collision and damage to both aircraft and dock. Too slow and the aircraft will not reach the dock, thereby causing some embarrassment to the pilot, but with several firm paddle strikes Brad solved this minor problem within seconds. The mooring ropes were secured to the tie-down points and the Twin Beech came to rest. The staff of the lodge opened the cabin door to allow the passengers to disembark onto the dock. Our flight time had been 29 minutes. After half an hour our flight continued into the Irvin Lake and the change over at both lodges was soon accomplished. Thanks for Brad for letting me fly right seat! We saw the Beech climbing away from the water

Eddie closed the door and started ‘November-Gulf’. We watched him taxi out to the middle of the lake, heard the thunderous roar of the R-985’s as he applied power and seconds later we saw the Beech climbing away from the water. Five minutes later Brad stared the port engine to get his Beech under control and then maneuvered the aircraft away from the dock while starting the starboard engine. |

|

|

Back at the Showalter’s place

A couple of day later we again returned to the Showalter’s and were invited by Eddie Showalter’s himself to accompany him on the Carroll Lake lodge run. Eddie is a jovial guy and a hard worker. He has 25,000+ hours on floatplanes, of which 17,000 hours on the venerable Beech 18’s. He learned to fly as a kid of just 15 years old by his dad. Conditions that morning were ideal, with warm temperatures and a clear blue skies. There was now hectic activity as both the Beech 18’s were preparing for departure. Loading all the gear and passengers is an interesting task and is all part of the ’wilderness experience’. Eddie offered one of us to sit in the right hand seat and so we agreed that Servaas would have the outbound sector to Carroll Lake, while I would occupy the seat on the return sector to the base. It was time to clamber into the Beech. Eddie closed the rear baggage door, released the mooring rope and quickly stared the port engine to get the Beech under control. He then maneuvered the aircraft away from the dock while starting the starboard engine. Once safely out on wider part of Trout Lake river, Eddie checked the movement of all the controls, rudder steering and power settings, which included fast taxiing before preparing for take-off. ‘Uniform-Oscar’ was making a VFR flight He retuned the radio frequency before advising ATC that ‘Uniform-Oscar’ was making a VFR flight from his base to Carroll Lake. Ed applied take-off power and started a curved take-off path. With the pair of radials roaring at take-off power, we soon came onto the ‘step’ and the old Beech soared into the air. During the climbing turn, I could see Highway 105 threading its way between the lakes and forest where we had driven earlier that day. The next 30 minutes the Twin Beech cruised smoothly westward across to the vast myriad of bays and inlets of Southern-Ontario. All too soon, the engine power was reduced and flaps were set for landing. Eddie alighted the floatplane on the water of Carroll Lake in foaming spray and then taxied towards the small dock of the lodge. The Beech 18 floatplane does not have brakes or reverse so the agile pilot must hop down onto the float, grab the mooring line, jump onto the dock, grab the wing strut and along with the mooring line, pull the plane alongside the dock. So as the Beech drifted slowly towards the jetty, Eddie unhitched his seat harness, opened the roof-top hatch, climbed out of the aircraft and moored his Beech. We left the aircraft in a rather undignified manner through the rear baggage door. Passenger exchange was completed Within half an hour the passenger exchange was completed and we were on our way again. Once the starboard engine fired up, the floatplane started to vibrate and then Ed signaled for the mooring rope to be released. Once safely clear of the dock on the waters of Carroll Lake, Eddie went through the take-off checklist. Due to the strong wind the waters of the Lake were rough and there were splashes of water on the windshield as the Beech began accelerating for her take-off run. During a climbing turn, I could see the lodge below and again amazed myself on how many lakes there are in this area. The return flight was smooth ans all too soon the descent was started towards the dark waters of Trout River and Ed alighted his Beech after the short 29 minutes flight. Shortly after passing the shoreline of the lake, there was a gentle splash as the floats brushed the water and the Beech decelerated as she settled onto the water. A high speed ‘on the step’ taxi followed and close to the dock Ed stopped both engines. The floatplane drifted towards the and the dockhand grabbed the Beech. Eddie is enthused about the rugged construction and good handling qualities of his Beechcrafts and Beaver, thereby making them ideal for operation in this demanding environment. The well-proven Pratt & Whitney R-985 engine is reliable and spares are in good supply. We thanked Eddie for his hospitality and the great trips in his unique Twin Beech. |

|

|

|