Kenora

|

DeHavilland Aircraft Company

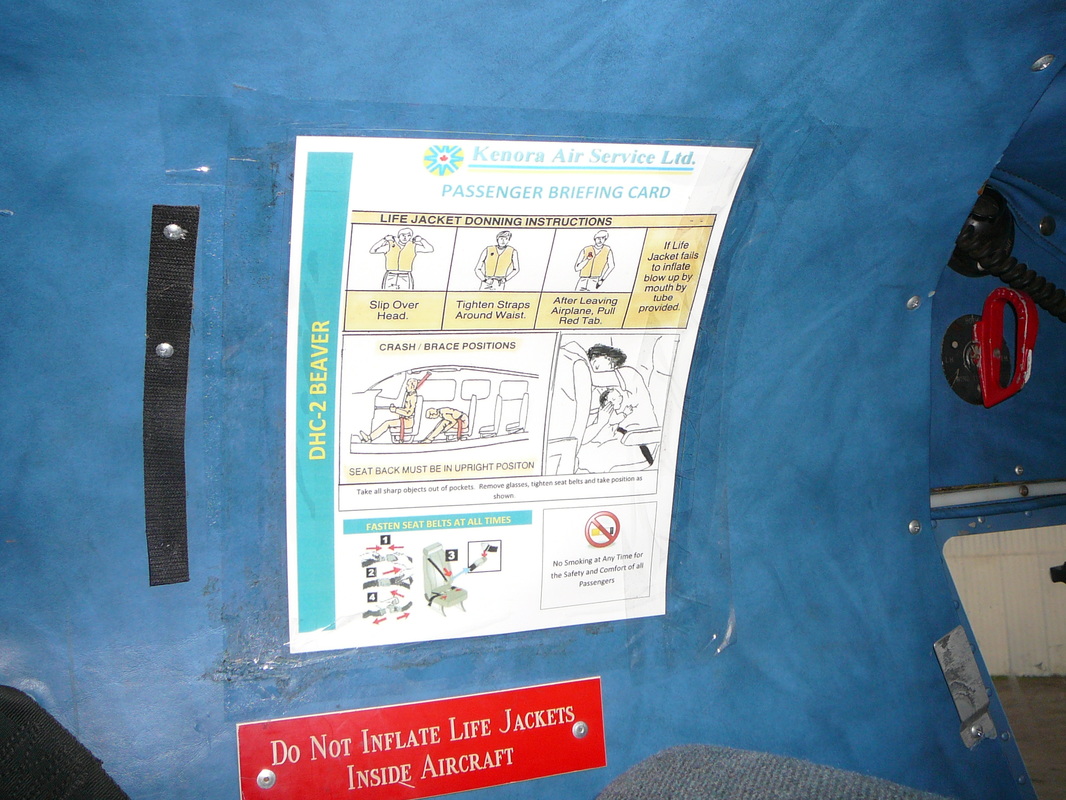

The De Havilland Aircraft Company was a British aviation manufacturer founded in 1920 of which Geoffrey de Havilland had been chief designer. He proposed the continuing to name the DHC line of aircraft after Canadian mammals. In September, 1946, de Havilland put together a design team. The new aircraft was specifically designed to be all-metal, unlike older designs like the famous Noorduyn Norseman. He used steel from the engine to the firewall, heavy aluminum truss frames with panels and doors throughout the front seat area, lighter trusses toward the rear and all monocoque construction aft. At the time de Havilland Canada was still a British company and there were plans to fit the evolving design with a British engine. This limited power, so the wing area was greatly increased in order to maintain STOL performance. When Pratt & Whitney Canada could buy war-surplus 450 hp (340 kW) Wasp Jr. engines at a low price, the aircraft ended up with extra power as well as the original long wing. The result was unbeatable STOL performance for an aircraft of its size. C-FJEI Note the ventral fin has been removed and seaplane fins installed for lateral stability. Manufactured in 1957, ‘Echo-India’, came off the line as a civil Beaver. Kenora Air Service is operating this Beaver since 1979 to access its outposts on the lakes and rivers north of Kenora C-FFHO Manufactured in 1949, C-FFHO, came off the line before the introduction of the porthole window. ‘Hotel-Oscar’ has spent a good part of its lifetime working as a sky-truck for the Canadian mining industry. Kenora Air Service purchased it last year (Sept. 2012) and is operating her every day since. As a civilian version, this stock Beaver has lower air induction, the original-style ventral fin and no porthole window aft of the cargo door, typical of early build Beavers. This Beaver wears the traditional de Havilland paint scheme of horizontal front-to-back speed stripe and registration letters in the tail band. C-FFHO is one of the few Beavers remaining without the porthole window. It still has the original ventral fin. She could easely hit obstacles as she swings around to taxi in en out. For this reason, seaplane fins on the horizontal stabilizers often replace the ventral fin. Next to this the smaller overall surface of the fins helps reduce the airplane's weathervaning tendency in a crosswind. Description of the De Havilland DHC-2 Beaver Normal Flight Procedures as describe in the Flight Manual of 1957

Engine warm-up: Throttle to give 1000 rpm. Move propeller lever fully forward to INCREASE RPM, as soon as oil pressure reaches 50 psi. After oil temperature has reached 40 degrees Celsius (100 dgr. F), adjust to smoothest engine speed between 1000 to 1400 rpm. Mixture lever FULL RICH. Select propeller lever to coarser pitch at 1000 rpm, to circulate the oil in the constant speed unit and propeller cylinder. Then return to INCREASE RPM. Never rush engine warm-up. Check oil pressure, fuel pressure and temperature. Tank feeds – check by rotating fuel selector to each tank. |

Notice the strobe light at the tip of the rudder of C-FJEI, which is not common with Beavers. The ventral fin has been removed and seaplane fins installed for lateral stability. Manufactured in 1957, ‘Echo-India’, came off the line at de Havilland as a civil Beaver. Kenora Air Service is operating this Beaver since 1979 to access its outposts on the lakes and rivers North of Kenora

|

|

Kenora Air Service C-FWDB on short final.

In the capable hands of Glenn Cranston she flew a freight run to the company’s lodge a Chase Lake. Kenora Air Service acquired this 1967 build Cessna 185E in 1979. Preflight Inspection of the Cessna 180K Visually check the airplane for general condition during the walk-around inspection. In cold weather, remove even small accumulations of frost, ice or snow from wing, tail and control surfaces. Also, make sure that control surfaces contain no internal accumulations of ice or debris. Prior to flight, check that pitot heater (if installed) is warm to touch within 30 seconds, with battery and pitot heat switches on. If a night flight is planned, check operation of all lights and make sure a flashlight is available. Cabin Pilot’s Operating Handbook – Available in the airplane. Control Wheel Lock – REMOVE. Ignition Switch – OFF. Avionics Power Switch – OFF. Master Switch – ON. Fuel Quantity Indicators – CHECK QUANTITY. Master Switch – OFF. Static Pressure Alternate Source Valve – OFF. Fuel Selector Valve – BOTH ON. Baggage Door – CHECK securely locked. Empennage Rudder Gust Lock – REMOVE. Floats – Drained and Check for damage. Control Surface – CHECK freedom of movement and security. Right wing trailing edge Aileron – CHECK freedom of movement and security. Right Wing Wing Tie-Down – DISCONNECT. Fuel Tank Vent Opening – CHECK for stoppage. Before first flight of the day and after each refueling, use sampler cur and drain small quantity of fuel from fuel tank sump quick-drain valve and fuel line quick-drain valve (located on bottom of fuselage below the cabin door) to check for water, sediment and proper fuel grade. Fuel Quantity – CHECK VISUALLY for desired level. Fuel Filler Cap – SECURE and vent unobstructed. Nose Static Source Openings (both sides of fuselage) – CHECK for stoppage. Propeller and Spinner – CHECK for nicks, security and oil leaks. Carburetor Air Filter – CHECK for restrictions by dust or other foreign matter. Engine Oil Level – CHECK. Do not operate with less than nine quarts. Fill to twelve quarts for extended flight. Left wing Fuel Quantity – CHECK VISUALLY for desired level. Fuel Filler Cap – SECURE and vent unobstructed. Left wing leading edge Pitot Tube Cover – REMOVE and check opening for stoppage. Stall Warning Opening – CHECK for stoppage. To check the system, place a clean handkerchief over the vent opening and apply suction; a sound from the warning horn will confirm system operation. Fuel Tank Vent Opening – CHECK for stoppage. Wing Tie-Down – DISCONNECT. Aileron – CHECK freedom of movement and security. |

|

|

River Air

River Air has two strategically located offices. Their main seaplane base is located near the town of Minaki, Ontario. Their sub-base is located on the Second Street Docks, on the harbor front of downtown Kenora. C-FMAQ De Havilland DHC-2 Beaver C-FMAQ has early construction number 14. This Beaver was built by de Havilland 65 years ago, in 1948 and delivered as CF-MAQ to the Province of Manitoba. During her long career this veteran workhorse served several bush plane outfits and finally ended up with River Air Ltd. in May 2007. View of the cargo door, wide enough to roll in a 45 gallon fuel drum. Its design makes the door removable for unimpeded loading, or it can be hooked to the wing strut, holding it open and out of the way as needed. C-GYKO Turbine-engine workhorse DHC-3 Otter C-GYKO was registered on in 1996 to River Air Ltd. This Otter was delivered to the United States Army in 1958. The Otter was allocated to the US Army Military Academy at WestPoint, New York, where it was to spend the entire of its military career. The mission of the Detachment was the support of training of the WestPoint cadets. The Otter continued in service until April 1973. The same year it entered the storage compounds of the Military Aircraft Storage and Disposition Centre (MASDC) at Davis-Monthan AFB. Within a year the Otter was sold to a private operator. She substantially damage in a crash at Franklin County Airport, Winchester, Tennessee, on March 17, 1975. In the course of a short field take off, during the initial climb in a left turn, the left wing dropped, the aircraft stalled and crashed back to the ground. The Otter was purchased by Ontario Central Airlines of Winnipeg, who brought the wreck to Winnipeg and rebuilt it with registration C-GYKO. Over the years that followed, ‘Kilo-Oscar’ has been operated by quite a number of Canadian bush carriers. In June 1996 she was finally sold to River Air Ltd of Pistol Lake, Minaki, Ontario. During 2002, the Otter flew down to Salina, Texas where it was converted to turbine power with a Garrett TPE-331 engine. Video

STARTING ENGINE Mixture – RICH. Propeller – HIGH RPM. Carburetor Heat – COLD. Throttle – OPEN ½ inch. Prime – AS REQUIRED. Master Switch – ON. Propeller Area – CLEAR. Ignition Switch – START (release when engine starts). Oil Pressure – CHECK. TAKE-OFF Wing Flaps – 0° or 20°. Cowl Flaps – OPEN. Carburetor Heat – COLD. Power – FULL THROTTLE and 2400 RPM Elevator Control – MODERATE TAIL LOW. Climb Speed – 85 KIAS. Wing Flaps – UP after obstacles are cleared. |

|

|

|

|

The cowling is off and all nine cylinders are visible. The mighty P&W 985 is burning 22 Imp gallons per hour. Note the exhaust tailpipe extension, with heat exchanger, which provides cabin heat for cold-weather flying. Hot air for heating the interior of the cabin is supplied by ram air passing through a heat exchanger tube in the engine exhaust system. From a four-way outlet at the center of the cockpit floor, the heated air is ducted to the pilot’s seat and front passengers feet and to two outlet grills in the cabin floor

|

Kuby’s Aircraft Ltd.

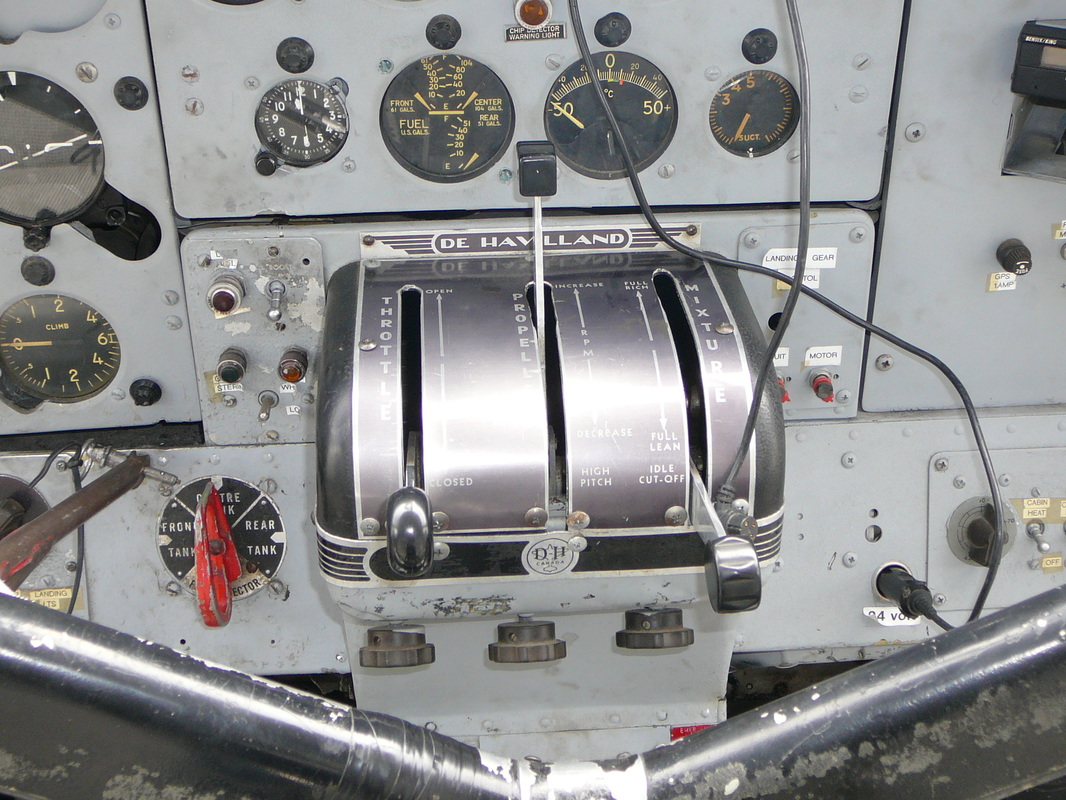

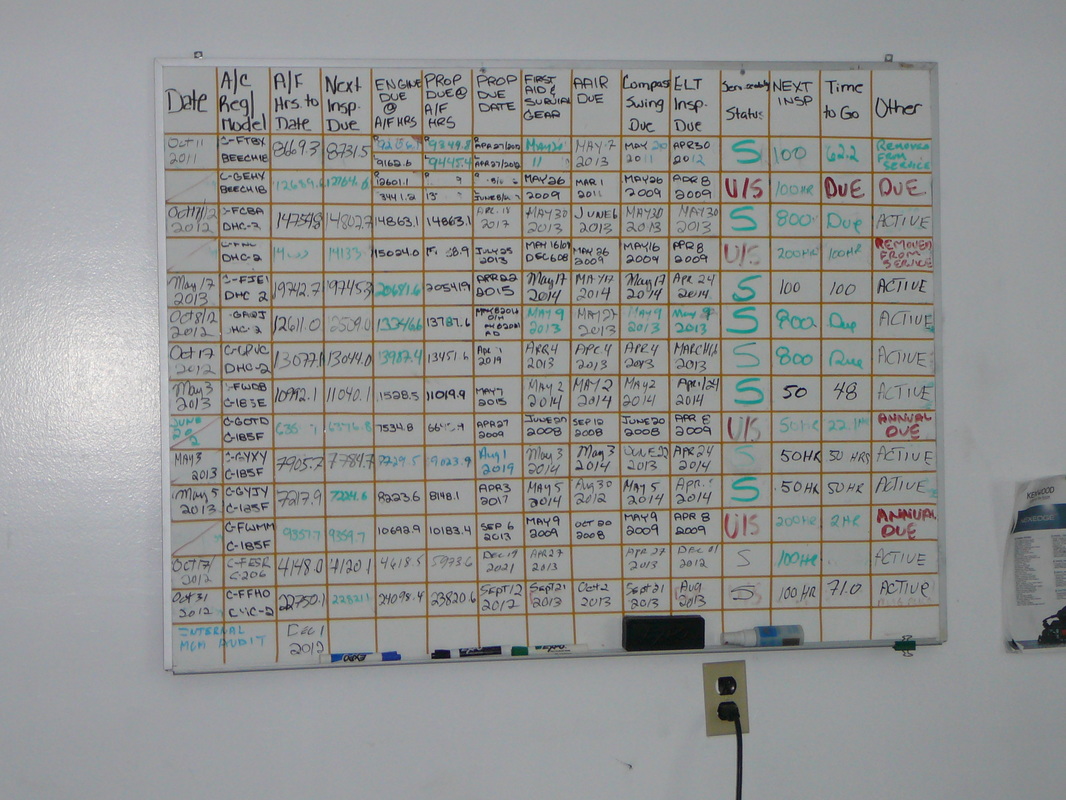

This area is just a 5 minute drive from the center of Kenora town and is located along 4th Avenue. Maintenance is done by Mr. Kuby jr. His old father is also still working in the shop and is doing the administration. Mr. Kuby jr. is a friendly fellow and he was so kind to show us around. Meanwhile we had a very interesting conversation about the maintenance of the bush plane. Fortunately men like the Kuby’s continue to keep venerable Beavers, Otters, Beech18’s and Cessna Skywagons flying strong. Several aircraft and wrecks lay around the yard. We noted the following: C-FTBX Beech 18 Kenora Air Service C-GEHX Beech 18 Kenora Air Service C-FJEI DHC-2 Kenora Air Service C-GAQJ DHC-2 Kenora Air Service CF-QWM Stinson 108-3 Voyager private C-FWMM Cessna185K Kenora Air Service C-GOTD Cessna185F Kenora Air Service C-GOTD Cessna185F Kenora Air Service C-GIUU Cessna180K private C-GYXY Cessna185F private C-FNOT DHC-2 restoration project No reg. DHC-2 restoration project CF-OCX C-FBCC Beech 18 WildCountry wreck C-FKEL Beech 18 WildCountry wreck No reg. Beech 18 wreck CF-OII Beech 18 Ignace Air Ltd. wreck C-FMAT DHC-2 wreck No reg. DHC-2 wreck No reg. Norseman frame only No reg. Norseman “Snowwater” artist wreck C-FJEP ?????? wing only C-FHKA ?????? wing only CF-GKJ Cessna185 wreck C-GAQJ The instrument panel of C-GAQJ still showing De Havilland on the lower chrome trim of the power lever console. Control levers are in military arrangement, from left to right, throttle, propeller and mixture. A shock-mounted flight instrument panel is provided for the pilot and incorporates and altimeter, turn-and-bank indicator, rate-of-climb indicator, air speed indicator, directional gyro and artificial horizon. Just partly visible to the right of the control column, is the cap of the oil filler. The oil tank is located aft of the fire-wall and is serviced from inside the cockpit through a filler at the base of the pedestal. The capacity is 5 ¼ imperial gallons. Geoffrey de Havilland The De Havilland Aircraft Company was a British aviation manufacturer founded in 1920 of which Geoffrey de Havilland had been chief designer. He proposed the continuing to name the DHC line of aircraft after Canadian mammals. In September, 1946, de Havilland put together a design team. The new aircraft was specifically designed to be all-metal, unlike older designs like the famous Noorduyn Norseman, using steel from the engine to the firewall, heavy aluminum truss frames with panels and doors throughout the front seat area, lighter trusses toward the rear and all monocoque construction aft. At the time de Havilland Canada was still a British company and there were plans to fit the evolving design with a British engine. This limited power, so the wing area was greatly increased in order to maintain STOL performance. When Pratt & Whitney Canada offered to supply war-surplus 450 hp (340 kW) Wasp Jr. engines at a low price, the aircraft ended up with extra power as well as the original long wing. The result was unbeatable STOL performance for an aircraft of its size. |

|

|

Kuby’s Aircraft Ltd.

C-GOTD Skywagon C-GOTD is owned by Kenora Air Services. This 185F was constructed in 1974. CF-GTP The Norseman frame on wheels in Kuby’s scrap yard is CF-GTP. This Norseman has been delivered to the US military in 1944. After the war she did operate for several bush plane operators. It is reported that this Norseman has crashed while in service with Sioux Narrows Airways. The fuselage has been at Kuby’s Aircraft Service facility since 1992. C-FGYY Noorduyn Norseman, C-FGYY played a starring role in the movie The Snow Walker. The film is about a Canadian bush pilot whose life is changed through an encounter with a young Inuit woman and their challenge to survive the harsh conditions of the Northwest Territories following an airplane crash. This Norseman was delivered to the US military in 1944. After the war she was sold to a private company and registered as CF-GYY in 1951. In the following years she served many Canadian bush plane operators. On June 25, 1985 the floats buckled on take off at Bishop Lake, Ontario in high winds and the aircraft overturned. Finally the damaged airframe appeared at Kuby’s Aircraft Repair facility in 1992, where she remains since. Jim Charlton let me know in November 2017 that Norseman C-FGYY is no longer wasting away at Kuby's Aircraft Repair. It has been moved to the Montréal Aviation Museum where a restoration to static display has begun.

Jim many thanks for the update. C-FWMM

Build in 1973, Cessna 185K C-FWMM is undergoing reconditioning at Kuby’s maintenance. Facilities such as Kuby’s continue to keep the Bush planes flying strong. |

|

|

Moored next to Kuby’s was this Stinson 108-3Voyager CF-QWM. The Stinson 108 was a popular general aviation aircraft produced by the Stinson division of the American airplane company Consolidated Vultee. Stinson was bought byPiper Aircraft in 1949. All Stinson model 108, 108-1, 108-2, 108-3 and 108-4 aircraft were built by Stinson at Wayne, Michigan. When Stinson sold the type certificate to Piper in 1949, approximately 325 airplanes of the 5,260 model 108s built by Stinson were complete but unsold. These 325 model 108s went to Piper as part of the sale. Piper then sold that inventory as the Piper-Stinson over the next few years. The fuselage was of fabric-covered steel tube. Aftermarket modifiers have obtained supplemental type certificates (STC) allowing conversion to an aluminum covering, like CF-QWM. Many different engines have been installed in the 108 by STC such as the Lycoming O-360,Franklin 220/220, Continental O-470. Total new production of the Stinson Model 108, by Stinson, was 5,260

|

|